Telecentric lens or zoom lens: which measurement solution should you choose?

Lens selection for measurement solutions: precision first or flexibility first?

There are usually two core requirements for measurement solutions: one is the pursuit of ultimate precision and stability (such as dimensional inspection of precision parts and assembly tolerance verification); the other is the need to flexibly respond to objects of different sizes (such as inspecting parts of different sizes on the same production line or observing details at different magnifications). These two types of requirements correspond precisely to the core advantages of telecentric lenses and zoom lenses.

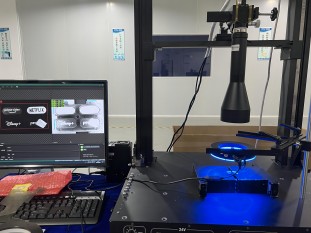

Telecentric Lens

The original purpose of designing a telecentric lens was to eliminate “invisible errors” in industrial measurement. Its core advantages lie in precision and stability:

1. No perspective error: The principal rays of a telecentric lens are nearly parallel to the optical axis (telecentricity is typically <0.1°), so the image size remains almost unchanged regardless of the position of the object being measured in the field of view (slight shifts to the left, right, front, or back). For example, when measuring the diameter of a cylindrical part, even if the part is slightly tilted, the telecentric lens can provide dimensions close to the actual size, while a standard lens may result in “overestimation” or “underestimation” due to perspective effects.

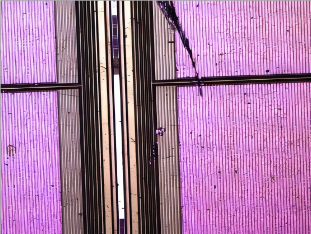

2. Extremely low distortion: The distortion rate is typically <0.1%, ensuring that the geometric shape of the image is nearly identical to that of the measured object. In scenarios requiring contour inspection (e.g., gear tooth profiles, PCB solder joint shapes), this “fidelity” capability is critical to avoid misjudgments caused by image distortion.

3. Strong resistance to environmental interference: Unaffected by surface reflections or minor positional vibrations of the measured object, the image clarity and consistency remain high as long as the object is within the depth of field.

Suitable Scenes:

Precision parts (such as mobile phone screws and chip pins) require dimensional measurement, flatness inspection, assembly gap verification, and other processes with accuracy requirements of ≥0.01 mm.

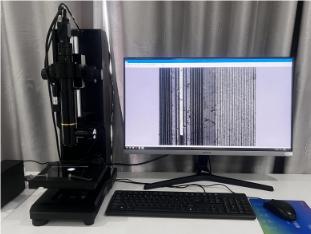

Zoom Lens

The core advantage of a zoom lens is that its magnification can be adjusted (for example, continuously adjustable from 0.7x to 4.5x), allowing the magnification to be quickly changed using a knob or motor without having to replace the lens. However, its accuracy characteristics differ significantly from those of a telecentric lens:

- Perspective error exists: The main light ray of the zoom lens is not parallel to the optical axis, and the position of the measured object is offset (for example, a little further away from or closer to the lens), which will cause changes in the image size. For example, when measuring the same object, the image is larger when it is closer to the lens and smaller when it is farther away, and the error may reach more than 0.5%.

- Relatively high distortion: Even with high-precision zoom lenses, the distortion rate is usually between 0.5% and 1%. Although this is better than ordinary fixed-focus lenses, it is far from the < 0.1% of telecentric lenses.

- Maximum flexibility: When dealing with objects of vastly different sizes, there is no need to stop the machine to change lenses. Simply turn the knob to switch the magnification. For example, if the same production line needs to inspect both electronic components the size of a fingernail and casings the size of a palm, the zoom lens can be quickly adjusted to suit.

Suitable Scene:

For scenarios where precision requirements are not extreme (error tolerance ≥ 0.1 mm) and frequent magnification switching is required, such as rapid screening of parts and preliminary detection of appearance defects (not involving precise dimensions).

One-sentence summary

- Select a telecentric lens: If your measurement scenario meets the requirements of “high accuracy (≤0.05mm), relatively fixed size of the measured object, and the need to eliminate errors caused by positional shifts,” such as measuring the diameter of a car bearing raceway or detecting the pin spacing of a chip, a telecentric lens is the only solution.

- Select a zoom lens: If your scene places more emphasis on “flexible magnification switching, large differences in the size of the measured object, and low accuracy requirements (≥0.1 mm),” such as appearance defect detection of toy parts and rough inspection of the label position on packaging bottles, a zoom lens can improve efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com