Ultra-Wide-Field Telecentric Measurement System | Precisely Captures Minor Wear on Metal Round Tubes

As a fundamental component in industrial production, the consistency of diameter dimensions and the smoothness of the outer contour of metal round tubes directly impact product performance and operational safety. Minor surface wear may cause localized diameter deviations, yet these differences are often too subtle to detect. The HM-1120 wide-field online Telecentric Measurement System, with its ultra-high measurement accuracy of 1.5μm, emerges as the ideal solution for addressing this inspection challenge.

I. Testing Requirements

To ensure the consistent quality of metal round tubes, inspections must meet the following core requirements:

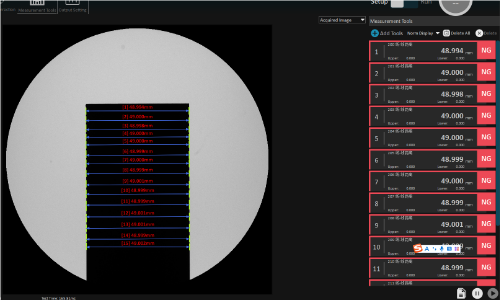

1. Measurement Interval: Measure the diameter every 5mm along the axial direction of the metal round tube to continuously track overall dimensional changes.

2. Inspection Objectives: Determine whether the product exhibits wear by comparing diameter data; simultaneously observe the outer contour shape to confirm it remains smooth.

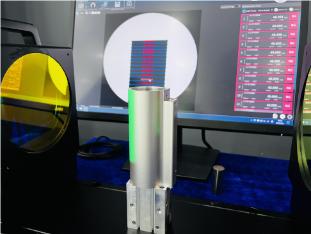

II. Detection Solution: Technical Advantages of HM-1120

The HM-1120 telecentric measurement system with an ultra-wide field of view serves as the core inspection equipment, achieving 1.5μm precision to capture minute dimensional variations and ensure product contour quality.

1. Real-time online measurement: Can be integrated into production lines for uninterrupted dynamic inspection of metal round tubes, eliminating the need for offline sampling. This enhances inspection efficiency and provides timely feedback on production status.

2. Ultra-High Measurement Accuracy: Achieves measurement precision down to 1.5μm, accurately identifying minute diameter variations caused by minor surface wear on metal tubes. This prevents missed defects due to insufficient accuracy inherent in traditional methods like calipers or micrometers.

3. Wide Field of View Coverage: Single measurements span extensive areas. Combined with 5mm interval requirements, this ensures inspection density while enabling holistic assessment of overall contour smoothness through comprehensive visual evaluation.

III. Test Result Image

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION