Industrial Camera Classification Guide (Essential Reading for Beginners)

Industrial cameras are indispensable optical components in machine vision solutions, playing a crucial role in capturing image information. However, for novice engineers just entering the machine vision inspection field, the complex classifications of industrial cameras can often be overwhelming. A slight misstep in model selection may lead to failure in achieving the desired visual inspection results. Today, we'll provide a comprehensive guide to industrial cameras, empowering you to confidently select the right one for your needs after reading this.

I. What Is an Industrial Camera?

An industrial camera is an image acquisition device specifically designed for industrial applications. It converts optical signals into electrical signals, thereby transmitting image information to subsequent processing systems. Unlike consumer-grade cameras used in daily life, industrial cameras offer superior image stability, transmission speed, and interference resistance. They can operate reliably for extended periods in complex industrial environments, meeting the high-precision and high-speed demands of machine vision inspection.

II. Classification of Industrial Cameras

Given the wide variety of industrial cameras, there are numerous classification methods based on different aspects such as interfaces, pixel counts, and image sensors, including:

1. By Interface Type

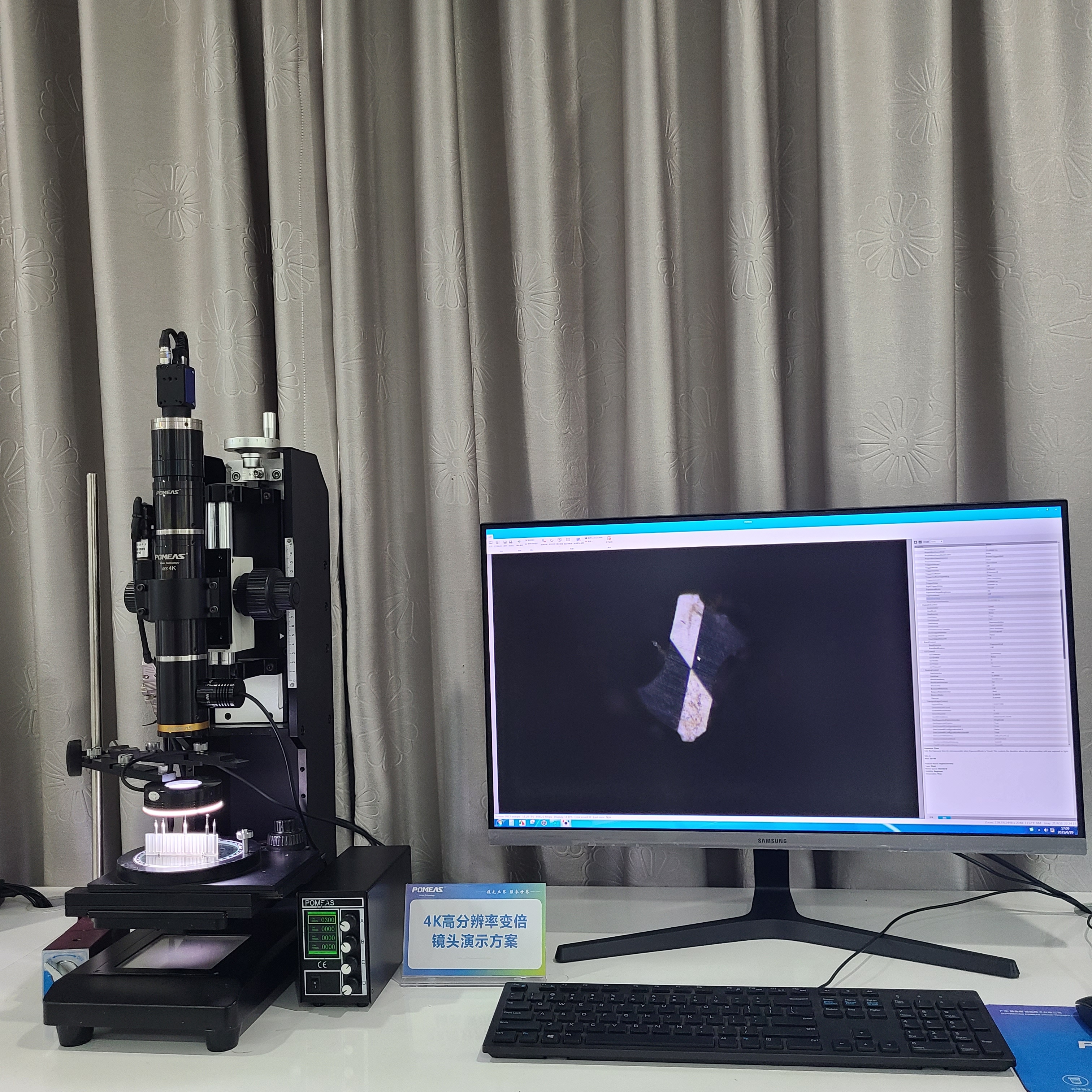

(1) HDMI Interface Industrial Camera: HDMI (High-Definition Multimedia Interface) is characterized by its high transmission speed and clear image quality. It enables direct transmission of high-definition images to displays and other devices without complex conversion, offering convenient installation and operation. This interface is ideal for scenarios demanding real-time image display, such as production lines requiring on-site monitoring and inspection.

(2) VGA Interface Industrial Camera: The VGA interface is a traditional analog signal interface. While its image transmission quality is slightly inferior to HDMI, it offers exceptional compatibility, connecting seamlessly with various legacy monitors, projectors, and other devices. For factories with older equipment, VGA interface industrial cameras represent a solid choice.

(3) Gigabit Ethernet Interface Industrial Cameras: These cameras transmit image data via Ethernet, offering advantages such as long transmission distances, high stability, and strong scalability. They facilitate seamless networking of multiple cameras, making them suitable for large-scale image acquisition and inspection in extensive production lines. This interface type is currently widely adopted across industrial applications.

2. Classified by Image Color

(1) Monochrome Industrial Cameras: Monochrome industrial cameras capture only black-and-white images, excelling in image detail and contrast. Since they do not process color information, they offer faster image transmission and processing speeds. They are suitable for scenarios focusing solely on grayscale information, such as product defect detection and dimensional measurement.

(2) Color Industrial Cameras: Color industrial cameras capture rich color information, making them suitable for scenarios requiring color recognition or microscopic imaging observation. For instance, they play a crucial role in detecting color variations on product surfaces or identifying parts marked with colored labels.

3. By Image Sensor Type

(1) CCD Sensor Industrial Cameras: CCD sensors offer advantages such as high sensitivity, low noise, and wide dynamic range, enabling them to capture clear images in low-light environments. However, they come with relatively high costs and power consumption, making them more prevalent in scenarios demanding exceptional image quality.

(2) CMOS Sensor Industrial Cameras: CMOS sensors offer high integration, low power consumption, and cost-effectiveness, coupled with fast image transmission speeds. With continuous technological advancements, CMOS sensor performance has increasingly approached that of CCD sensors. They now meet requirements in most industrial inspection scenarios and represent the mainstream sensor type for industrial cameras.

4. Classified by Pixel

(1) Megapixel Industrial Cameras: Megapixel industrial cameras offer relatively low resolution, making them suitable for scenarios with less stringent accuracy requirements, such as rough visual inspections of large products.

(2) 5-Megapixel Industrial Cameras: 5-megapixel industrial cameras provide medium resolution, meeting the accuracy demands of most industrial inspection tasks. They are widely used in applications like product defect detection and dimensional measurement.

(3) 10-megapixel industrial cameras: These cameras deliver extremely high resolution, capturing minute image details. They are suitable for scenarios demanding the highest inspection accuracy, such as semiconductor chip inspection and microscopic observation of precision components.

III. Key Considerations for Selecting Industrial Cameras

(1) Determine the appropriate interface type: Select based on factors such as production line equipment conditions, transmission distance, and networking requirements. For newer production line equipment with high real-time display demands, HDMI interfaces are a solid choice. For older factory equipment, VGA interfaces offer superior compatibility. For large-scale production lines requiring multiple cameras to work in tandem, Gigabit Ethernet interfaces are more suitable due to their extended transmission distance, high stability, and strong scalability.

(2) Define inspection objectives: For tasks like product defect detection or dimensional measurement, monochrome industrial cameras excel in image detail, contrast, and faster transmission/processing speeds, enhancing inspection efficiency and accuracy. For color recognition or microscopic imaging, color industrial cameras capture rich color information to meet inspection requirements.

(3) Consider sensor type: In low-light environments demanding exceptional image quality—such as precision electronic component inspection—CCD sensor industrial cameras excel due to their high sensitivity, low noise, and wide dynamic range. For most routine industrial inspection scenarios, CMOS sensor industrial cameras better meet requirements with their high integration, low power consumption, cost-effectiveness, and faster image transmission, while reducing overall solution costs.

(4) Select pixels based on inspection accuracy: For rough appearance inspections of large products, a million-pixel industrial camera suffices and offers lower cost. For most industrial inspection scenarios, such as defect detection and dimensional measurement of general products, the medium resolution of 5-megapixel industrial cameras provides sufficient accuracy. However, in scenarios demanding extremely high inspection precision—such as semiconductor chip inspection or microscopic observation of precision components—10-megapixel industrial cameras capture minute image details to ensure detection accuracy.

Through the above introduction to industrial camera classifications and key selection points, we believe that as a novice engineer in the machine vision inspection industry, you now have a clearer understanding of industrial cameras. Should you have any further questions, POMEAS can provide professional industrial camera selection and solution design services to help you complete your machine vision inspection projects more efficiently.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com