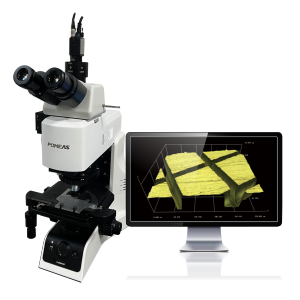

In the fields of precision manufacturing and quality inspection, the accurate measurement and analysis of surface topography are critical to ensuring product performance and reliability. Leveraging its deep technical expertise and innovative capabilities, POMEAS has introduced the Super-Depth-of-Field Autofocus Microscope. With its exceptional image processing capabilities and intelligent motorized control system, this instrument redefines the standards for surface topography inspection.

I. Exceptional Image Processing Capabilities: Revealing Every Detail with Crystal-Clear Precision

1. Self-developed analytical software, featuring comprehensive functionality and user-friendly operation.

The POMEAS microscope is equipped with proprietary professional analysis software that integrates image acquisition, processing, and measurement. It supports analysis of multiple surface topography parameters (such as roughness and contour) and generates intuitive inspection reports. Featuring a clean, intuitive interface and optimized workflow, the software enables even non-specialists to quickly master its use, significantly boosting inspection efficiency.

2. Real-time multi-focus fusion captures crystal-clear images in an instant.

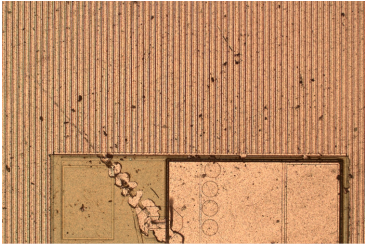

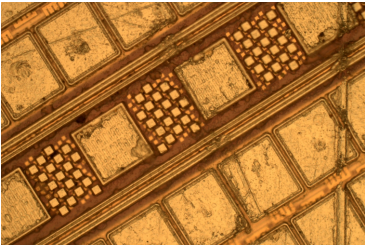

Traditional microscopes often produce blurred local areas when observing complex surfaces due to insufficient depth of field. POMEAS microscopes overcome this technical limitation by employing real-time multi-focus fusion technology to automatically synthesize fully in-focus, clear images. This eliminates the need for repeated focus adjustments, enabling one-click acquisition of the entire surface view—making it particularly suitable for inspecting uneven, textured samples.

3. Intelligent image stitching, expanding the field of view

For large-sized samples or scenarios requiring comprehensive analysis, the microscope features image stitching functionality that automatically combines multiple high-resolution images to generate seamless panoramic views. Users can both grasp the overall morphology at a macro level and examine local details at a micro level, enabling flexible inspection with a single instrument.

II. Electric Control System: Precise Control, Stable and Efficient

1. Motorized Objective Changer, Quickly Adapting to Different Inspection Requirements

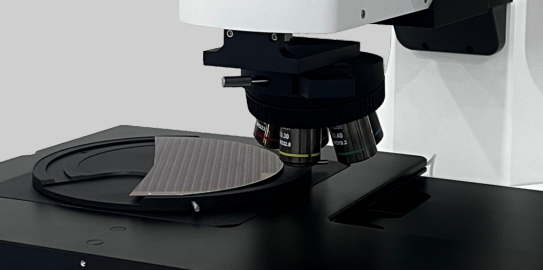

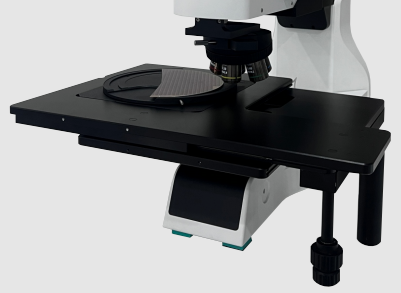

The microscope is equipped with an electric objective changer, enabling rapid switching between multiple objectives (such as 5×, 10×, 20×, etc.) without manual replacement. This eliminates human error while reducing inspection preparation time. Users can freely select magnification levels based on sample characteristics, effortlessly handling topography measurements ranging from micrometers to millimeters.

2. Motorized Stage, Precision Positioning and Motion Control

The motorized stage supports precise X/Y/Z-axis movement with micrometer-level positioning accuracy. Programmable inspection paths enable automated batch testing. Combined with the software's autofocus algorithm, the stage automatically adjusts sample height to ensure every inspection point remains within the optimal focal plane, significantly enhancing measurement repeatability and accuracy.

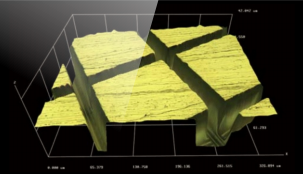

III. 3D Measurement: Effortlessly Capture Three-Dimensional Features

POMEAS microscopes simplify the 3D imaging process through coordinated operation between the Z-axis focusing module and software:

1. One-click 3D imaging: The Z-axis module automatically scans surface height variations, while the software generates real-time 3D topography maps to visually display features like concavities, convexities, and slopes.

2. Precise 3D Measurement: Utilizing focus stacking technology, the software extracts surface elevation data to calculate parameters like roughness and flatness, providing quantitative metrics for quality control.

3. Rapid Focus Adjustment: The responsive controller supports manual fine-tuning or autofocus, ensuring seamless operation even with dynamic samples or rapid inspection scenarios.

IV. Free Inspection Service: Experience Professional Quality at Zero Cost

To lower the barrier for corporate technology upgrades, POMEAS now offers complimentary inspection services! Simply submit your samples to receive one-on-one inspection support from professional engineers, along with detailed morphological analysis reports and optimization recommendations. Whether for new product development verification or production process quality control, POMEAS microscopes serve as your trusted inspection partner.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com