In the field of bearing manufacturing and quality control, accurate measurement of internal and external dimensions is the core link to ensure performance and reliability. In the face of increasingly stringent tolerance requirements (such as P5, P4 level precision bearings), the traditional means of measurement is often not satisfactory. Such as:

1、Vernier calipers, micrometers

The precision is not high and the work efficiency is low, with the risk of damaging the bearings.

2、Plug Gauge, Ring Gauge

Measurement function is single, can't get the specific size data of the bearing, and it is easy to produce wear and tear to affect the accuracy of the product after many times of use, and the working efficiency is low.

3、Coordinate Measuring Machine

The equipment cost is high, the operation is extremely complex, and the intelligent realization of a single contact scanning, can not meet the needs of high-volume inspection.

POMEAS Image Gauge combines high resolution optical imaging, precision motion control and intelligent image analysis algorithms to provide the ultimate non-contact, high efficiency and high accuracy solution for internal and external bearing diameter measurement. The advantages are as follows:

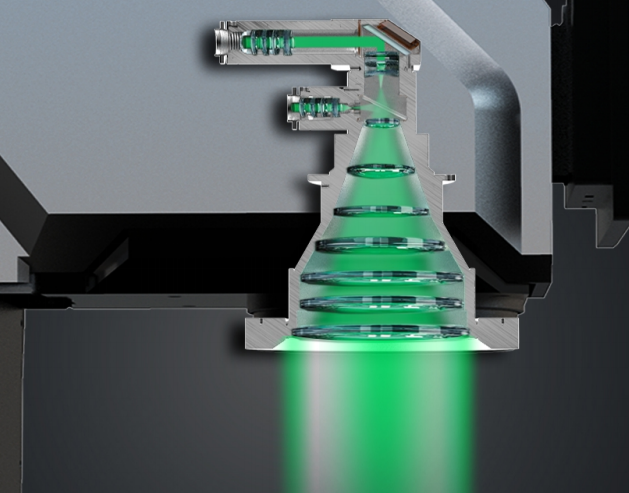

1、Micron-level optical accuracy

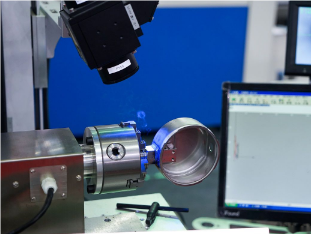

Adopting ten million double telecentric lenses with high-resolution industrial cameras to easily capture clear images of bearing edges, easily realizing micron-level repeatable measurement accuracy to meet the measurement accuracy requirements of bearings.

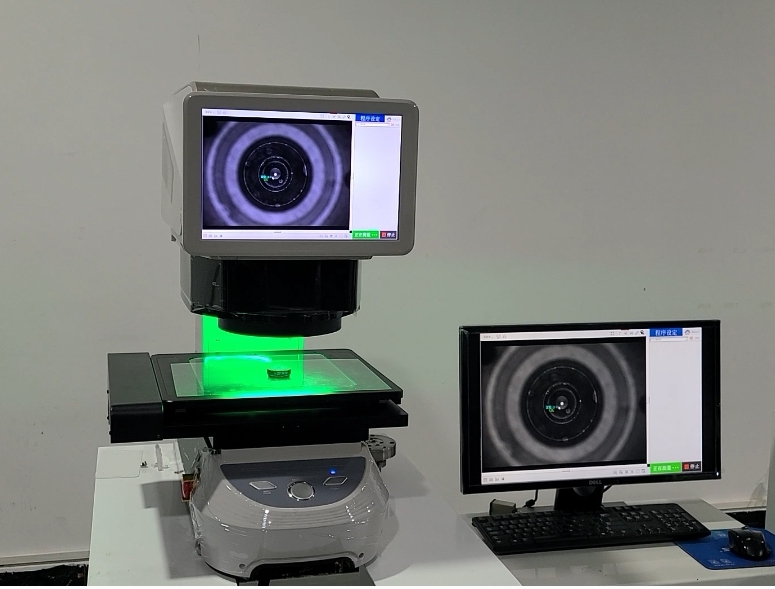

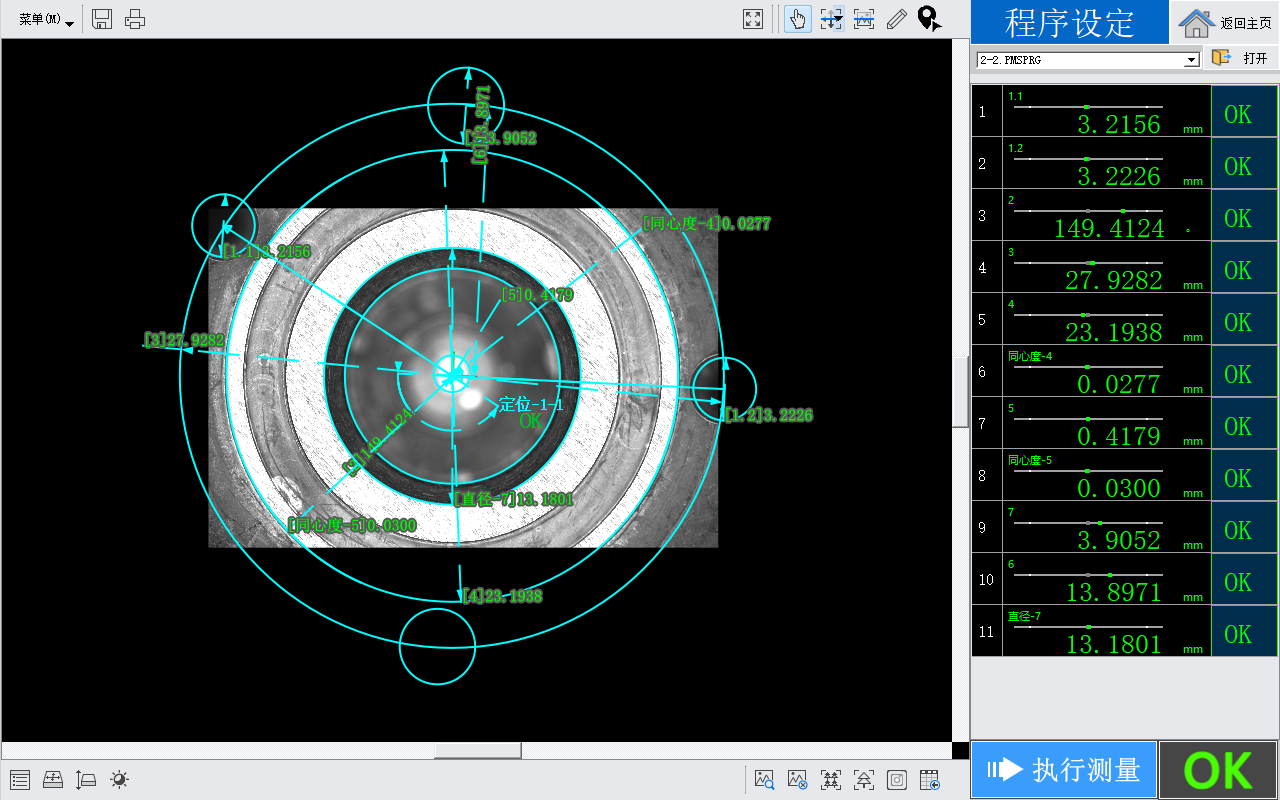

2、Intelligent and fully automatic measurement

One-button fast measurement, automatic recognition of bearing contour positioning, instantly complete the bearing inside and outside diameter, roundness, chamfering and other dimensions of the measurement, improve the measurement work efficiency.

3、POMEAS AI Vision Intelligent Measurement Software

Accurately fitting the inner and outer ring profiles, quickly calculating bearing roundness, corrugation and other shape and position tolerances, simple programming, even a novice can be proficient operation within 1 hour.

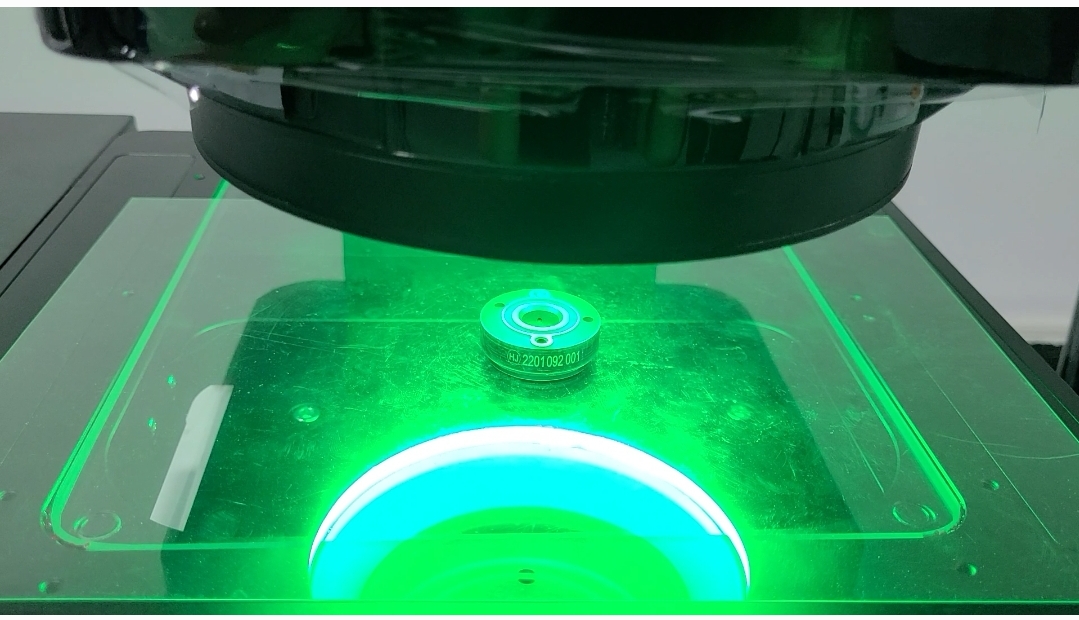

4、Multiple light sources, free lighting

With coaxial light, ring light, bottom light and other multiple light sources, clearly highlighting the bearing inner and outer ring edges, can adapt to different materials such as scratches, corrosion and other appearance inspection.

Detection Effect

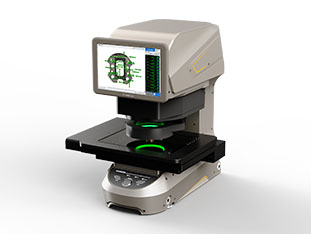

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION