Programmatic Background:

In the field of electronics manufacturing, aerospace and other precision manufacturing, blind holes, as a special structure, are widely found in all kinds of parts, especially in the production of circuit boards in the manufacturing process. The quality of blind holes directly affects the performance and reliability of the product, for example, in circuit boards, blind holes assume an important role in the electrical connection between the layers, the size and shape of the accuracy of the substandard, which may lead to poor signal transmission, short-circuit and other problems, which in turn affect the normal operation of the entire electronic equipment. Therefore, accurate inspection of blind vias is crucial.

Blind Hole Inspection Difficulties:

Structurally, blind holes are open at one end and closed at the other, which makes it difficult for traditional contact measuring tools to penetrate into the holes for comprehensive measurements, which can easily cause damage to the hole wall, and at the same time, it is impossible to accurately obtain the dimensional information of the bottom of the holes. Moreover, the diameter of blind holes is usually small, and some of them even reach the micrometer level, which puts forward very high requirements on the resolution and accuracy of measuring instruments. In addition, the depth-to-diameter ratio of blind holes may be large, which is prone to problems such as light blockage and signal attenuation during the measurement process, resulting in inaccurate measurement data.

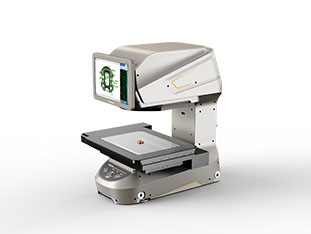

With automatic lightening, high-precision optics, and AI intelligent software, the Image Measuring Instrument is able to effectively solve the challenges of blind hole inspection and provide accurate size and shape measurement results.

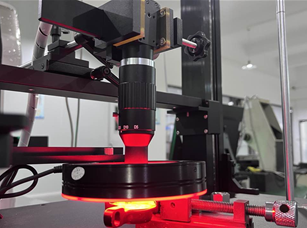

1、In terms of dimensional measurement, it can accurately measure the diameter, depth, aperture change and other parameters of blind holes through high-precision sensors and optical systems. For example, when laser scanning technology is used, the laser beam can penetrate deeply into the interior of the blind hole, and through the analysis and calculation of the reflected signals, the diameter size of each position of the blind hole is derived, and the measurement accuracy can reach the micrometer or even nanometer level. For depth measurement, the high-precision measuring instrument can utilize displacement sensors to accurately record the distance moved by the measuring probe from the opening to the bottom of the hole, so as to obtain the depth data of the blind hole.

2、In terms of shape measurement, the high-precision measuring instrument is capable of detecting shape errors such as roundness, cylindricity and perpendicularity of blind holes. It constructs a three-dimensional model of the blind hole through scanning and data acquisition of multiple cross-sections of the inner wall of the blind hole, and then compares and analyzes it with the design standard model to derive the specific value of the shape error. For example, if there is an out-of-roundness in the blind hole, the measuring instrument can evaluate the shape accuracy of the blind hole by calculating the difference between the maximum diameter and the minimum diameter through the measurement data of different angles.

Through these precise measurements, engineers are able to gain a comprehensive understanding of the quality of the circuit board's blind vias and determine whether they meet the design requirements. If the measurement data is within the design tolerance, the blind vias are qualified; otherwise, the production process needs to be adjusted and optimized to ensure the quality and performance of the circuit board.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com