In the precision machinery transmission system, gear center distance as a core parameter, directly affecting the meshing accuracy, transmission efficiency and service life, for example: the center distance error of more than 0.05mm may lead to increased gear wear, noise exceeds the standard, and even triggered by equipment downtime.

Traditional inspection means such as vernier calipers, micrometers are limited by the error of manual operation, while the coordinate measuring machine, although the accuracy of the standard, but there are low efficiency, contact measurement easy to damage the workpiece and other pain points.

The current mainstream detection schemes are as follows:

1. Mechanical gauges: suitable for on-site rapid calibration, but the accuracy is limited by the operator's experience and cannot meet the demand for μm-level testing;

2. Coordinate measuring machine: through the probe contact scanning to obtain data, the accuracy can be up to μm level, but a single piece of measurement time-consuming 5-10 minutes, and need to be operated by professionals;

3. Optical projector: the use of contour magnification projection for comparison, but there are subjective judgment errors, and poor adaptability to complex tooth shape.

Detection Program:

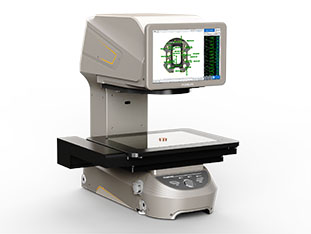

The POMEAS IMAGE 3 series of image-based dimensional measuring instruments enables rapid measurement of gear center distance, diameter, tooth pitch, etc. by means of non-contact optical imaging technology.

- One-touch operation:Equipped with AI edge detection algorithm, automatic gear contour identification and data collection is completed within 3 seconds;

- Non-contact measurement:The use of telecentric lenses with high-resolution CMOS sensors avoids deformation of workpieces caused by mechanical contact;

- Full dimensional analysis:It can synchronously output 12 parameters such as center distance, tooth pitch, tooth shape error, etc., with a measurement accuracy of ±1μm.

POMEAS solution is not only applicable to gear manufacturing, but also extends to bearings, precision molds and other fields that require micron-level control. Due to its simple operation and wide range of measurements, it can be applied to new energy, semiconductors and other industries.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION