Telecentric lenses enable high-precision coplanarity inspection of electronic component leads

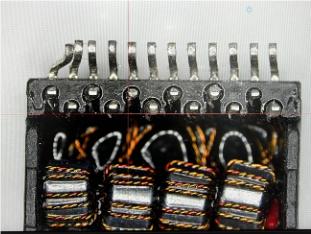

In today's rapidly evolving electronics manufacturing industry, quality control of electronic components has become increasingly critical. Among these, pin coplanarity serves as a vital metric for evaluating component performance and reliability. Failure to meet pin coplanarity standards can lead to issues such as poor soldering and circuit connection failures, severely impacting the quality of electronic products. Achieving high-precision pin coplanarity inspection for electronic components is no simple task. The advent of telecentric lenses has provided an effective solution to this challenge.

I. Challenges in Co-Planarity Inspection of Electronic Component Leads

Electronic component pins typically feature small dimensions, high density, and numerous components, presenting significant challenges for coplanarity inspection. For example:

1. Pin dimensions are minute, with some measuring only a few millimeters or even smaller, making it difficult for traditional inspection methods to accurately capture subtle height variations.

2. The spacing between pins is often extremely narrow, leading to mutual obstruction and creating blind spots during inspection that prevent comprehensive acquisition of each pin's positional data.

3. Environmental factors like light fluctuations and vibrations can interfere with detection accuracy, complicating the precise determination of pin coplanarity.

4. For mass-produced electronic components, detection efficiency is a critical consideration. Traditional methods are often slow, failing to meet the demands of large-scale production.

II. Detection Plan

1. High-Definition Camera - 5MP Monochrome Industrial Camera: This camera features 5 million pixels, delivering high-resolution images that clearly capture the detailed characteristics of electronic component pins. Monochrome imaging reduces color interference while enhancing image contrast, facilitating subsequent image processing and analysis. It provides high-quality raw image data for precise inspection.

2. Telecentric Lens LTCM0118-261-G: As the core component of this solution, this telecentric lens features a unique optical design that effectively eliminates perspective distortion. It ensures consistent object imaging dimensions across varying working distances, laying the foundation for precise measurement of pin height differences.

3. Vision Light Source - Planar Light: The planar light source delivers uniform, stable illumination that minimizes the impact of surface reflections on electronic components. This enhances the clarity of pin edge features, enabling high-definition cameras to capture complete and accurate image information, thereby improving detection reliability.

III. Advantages of Telephoto Lenses

1. Eliminating perspective distortion is one of its core advantages. Conventional lenses produce a perspective effect where objects appear larger up close and smaller in the distance due to varying distances between different parts of the object and the lens, leading to measurement inaccuracies. The optical design of telecentric lenses ensures that the principal rays remain parallel to the optical axis. Regardless of how an object moves within the working distance, the image size remains constant, effectively preventing perspective distortion from affecting measurement precision.

2. High resolution and high contrast. Telecentric lenses clearly render object details, particularly for minute electronic component pins, enabling precise edge and contour differentiation. This enhances image quality, providing a solid foundation for subsequent image processing and measurement.

3. Wide working distance range. Telecentric lenses maintain stable imaging quality and measurement accuracy across a wide working distance range. This eliminates the need for frequent lens repositioning when inspecting electronic components of varying sizes and types, increasing inspection flexibility and convenience.

4. Strong interference resistance. Telecentric lenses effectively suppress interference factors such as reflections and scratches on electronic component surfaces. This minimizes their impact on imaging, ensuring stable and accurate inspection results.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com