Do you know the answers to these questions about motorized zoom lenses?

In the field of optical equipment, motorized zoom lenses have become indispensable key components across numerous industries due to their flexible and versatile characteristics. However, for many people, motorized zoom lenses still hold an air of mystery. Below, we provide detailed answers to some common questions about motorized zoom lenses.

I. What controls the magnification of an electric zoom lens?

The precise zoom adjustment capability of motorized zoom lenses relies primarily on their intricate internal mechanical structures and advanced control systems. For example:

1. The Core Function of the Control Board

Motorized zoom lenses typically come equipped with a dedicated control board, which acts as the lens's brain, responsible for receiving and processing various commands. By connecting to the motor drive module inside the lens, the control board precisely regulates the motor's operation. As the power source, the motor drives the movement of the lens's internal optical elements, altering the path of light transmission to achieve zoom magnification adjustment.

2. Convenience of Programmed Adjustment

Programmed magnification adjustment stands as a major advantage of motorized zoom lenses. Users can tailor lens magnification changes by writing specific programs according to practical needs. For instance, in automated inspection systems, programs can automatically adjust lens magnification based on preset inspection workflows to accommodate objects of varying sizes and shapes. This intelligent adjustment method not only enhances operational efficiency but also minimizes human operational errors.

3. Synergistic Application with Measurement Programs

In measurement and microscopic observation, motorized zoom lenses form an ideal partnership with measurement programs. Measurement software can precisely calculate parameters such as the size and shape of observed objects based on the lens's magnification data. For instance, in industrial part dimension measurement, after capturing a clear image with a motorized zoom lens, the measurement program can rapidly and accurately determine all dimensional parameters of the part, providing robust evidence for quality control. Simultaneously, in microscopic observation, measurement software assists researchers in performing quantitative analysis of microstructures, driving the advancement of scientific research.

II. What are the application scenarios for motorized zoom lenses?

Motorized zoom lenses have found extensive applications across multiple fields due to their flexible magnification adjustment capabilities and high-precision imaging performance.

1. Industrial Inspection Field

In industrial production, product quality inspection is a critical process. Motorized zoom lenses can be used for visual inspection, dimensional measurement, and defect identification of various industrial components. For instance, in the electronic chip manufacturing industry, where minute components on chips demand extremely high dimensional accuracy, motorized zoom lenses provide high-magnification, clear images. This enables inspectors to detect minute defects such as scratches and cracks on chip surfaces, ensuring chips meet quality standards.

2. Machine Vision Applications

Machine vision technology is a vital component of modern industrial automation, with motorized zoom lenses serving as core elements within machine vision systems. On automated production lines, these lenses capture real-time product imagery and enable image processing algorithms to classify, locate, and identify products. For instance, in the food packaging industry, motorized zoom lenses enable rapid and accurate recognition of labels, dates, and other information on packaging, ensuring product compliance.

3. Scientific Research and Education

In scientific experiments, motorized zoom lenses serve as essential tools for microscopic observation. Researchers can adjust the lens magnification to conduct in-depth observation and study of the microscopic world. For instance, in biological research, motorized zoom lenses help scientists observe cellular morphology, structure, and dynamic changes, providing crucial support for life science advancement. In education, these lenses serve as teaching demonstration tools, enabling students to intuitively grasp the mysteries of the microscopic world and spark their interest in science.

III. What is the zoom range of an electric zoom lens?

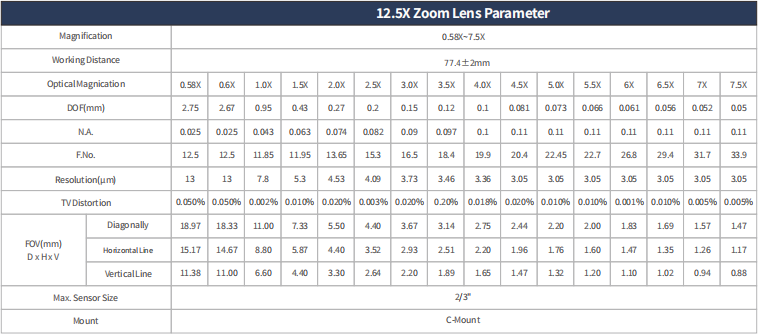

The magnification range of motorized zoom lenses varies depending on the model and intended use. Taking a common motorized zoom lens as an example, its magnification range is 0.58x to 7.5x.

1. Applications of Low Magnification (0.58x)

In low magnification mode, motorized zoom lenses offer a wide field of view, making them suitable for observing and monitoring expansive scenes. In industrial inspection, low magnification enables rapid identification of the approximate location of inspection targets, thereby enhancing inspection efficiency.

2. Applications of High Magnification (7.5x)

In high-magnification mode, motorized zoom lenses magnify object details to deliver high-resolution imagery. For scientific observation, high magnification enables researchers to examine intricate microscopic structures—such as organelles within cells or the micro-morphology of nanomaterials. In industrial inspection, high magnification assists inspectors in detecting minute surface defects on products, including bent pins on electronic components or faulty soldering.

3. Advantages of Continuous Zoom Adjustment

The zoom ratio of the motorized zoom lens can be continuously adjusted between 0.58x and 4.5x. This flexibility allows the lens to adapt to various observation requirements. Users can freely adjust the magnification according to actual conditions without changing lenses, significantly improving work efficiency and usability.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com