Against the backdrop of rapid advancements in smart manufacturing and precision engineering, industrial inspection demands increasingly higher standards for measurement tools in terms of efficiency, accuracy, and ease of use. To meet the core demands of modern production lines for “speed, precision, and traceability,” the AI-IMAGE Image Dimension Measurement Instrument software was developed. As an innovative product integrating artificial intelligence and computer vision technology, it offers a one-stop digital solution for manufacturing, research institutions, and quality control sectors. Its key advantages include low-threshold operation, high-precision measurement, and multi-scenario adaptability.

I. Measurement Function Analysis

In addition to standard measurement elements such as length, width, circularity, and angle, specialized measurement features are available, including screw measurement, inner/outer diameter measurement, gear measurement, rectangle measurement, and point cloud extraction. These assist in rapid measurement, making the process faster and simpler.

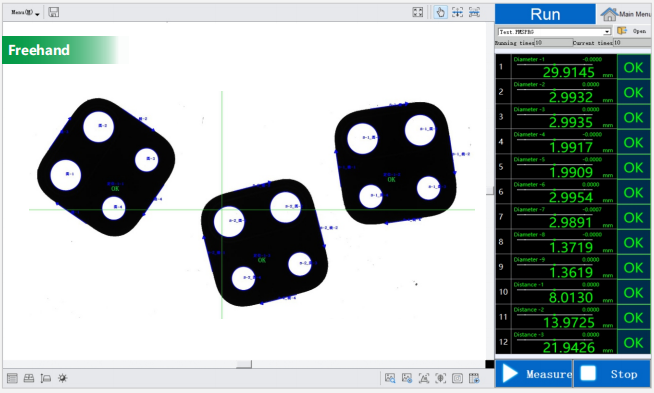

1. Multi-scenario Rapid Measurement Tool:

① Screw Measurement: Automatically identifies thread parameters (pitch, lead angle), head diameter/shank diameter, and length, supporting thread classification (metric/imperial).

② Circular Inner/Outer Diameter Inspection: Precisely measures inner/outer diameters, center coordinates, and roundness error of circular parts using edge-fitting algorithms.

③ Gear Measurement: Automatically identifies tooth count, module, and pressure angle; supports analysis of pitch circle diameter, root circle diameter, and pitch deviation.

④ Rectangular/Polygonal Measurement: Rapidly obtains side lengths, angles, and diagonal lengths, supporting irregular polygon contour extraction.

⑤ Point Cloud Extraction: Restores 3D object surface topography via high-precision point cloud algorithms, supporting point cloud export and reverse engineering.

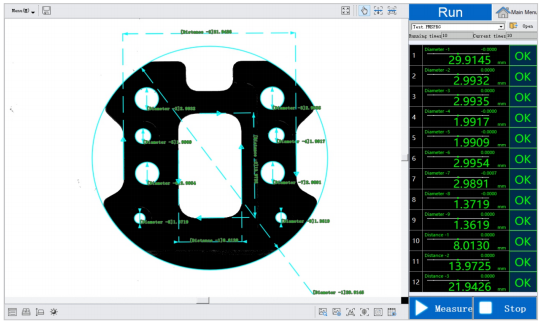

2. Intelligent Detection Module:

① Scan-to-Identify: Integrates OCR with barcode/QR code recognition to automatically link product batches and specification parameters, enabling measurement data traceability.

② Profile Deviation Detection: Compares actual contours against design CAD models, outputs deviation heatmaps, and supports GD&T (Geometric Dimensioning and Tolerancing) analysis.

③ Pitch and Angle Inspection: Automatically calculates pitch, tooth angle, and sprocket offset for transmission components like chains and gears.

3. Automation and AI Enhancement:

① One-Click Measurement: Automatically identifies measurement areas and generates reports using template matching technology, reducing manual steps.

② AI Edge Optimization: Enhances edge detection in low-contrast images through deep learning models, improving measurement accuracy in complex scenarios.

③ Dynamic Compensation: Automatically corrects measurement errors based on ambient lighting and lens distortion to ensure stable results.

II. Technical Advantages and Differentiation

1. Low-threshold Operating Design:

① Visual Interface: Features a drag-and-drop tool layout for quick addition of measurement elements and parameter adjustments.

② Intelligent Guidance: Guides users through complex measurement workflows (e.g., gear parameter setup) via animated tutorials and voice prompts.

③ Multilingual Support: Adapted for global users with Chinese-English language switching and customizable terminology libraries.

2. High Precision and Compatibility:

① Sub-pixel accuracy: Achieves micrometer-level measurement through sub-pixel edge detection algorithms (dependent on hardware resolution).

② Multi-format import/export: Supports CAD formats including DXF, STEP, and IGES; measurement data can be exported as Excel/PDF reports.

③ Cross-platform compatibility: Compatible with Windows/Linux systems; supports diverse image inputs such as industrial cameras, microscopes, and mobile phone cameras.

3. Industry-Specific Customization Capabilities:

① Secondary Development Interface: Provides Python/C++ SDKs, enabling users to integrate custom algorithms or connect to MES/ERP systems.

② Industry Template Library: Pre-configured standard measurement templates for electronics, automotive, aerospace, and other sectors accelerate deployment cycles.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com