In the field of image dimension measurement, the lens serves as the core optical component, directly determining the device's measurement accuracy, efficiency, and applicable scenarios. The two primary lens types commonly used are double-telecentric lenses and 4K HD zoom lenses. Both must be precisely matched with specific device models to achieve optimal performance. Below, we will explore lenses using the POMEAS Image Dimension Measuring Instrument (Flash Measurement Instrument) image3 series as an example.

I. Double-Telecentric Lens

1. Core Optical Properties and Hardware Synergy (Continuing Core Data)

① Dual telecentric structure + low distortion: Object-side telecentricity eliminates parallax, while image-side telecentricity prevents projection distortion. Full-field distortion rate ≤0.03%, with deformation error of only 0.09mm within the 300mm measurement range. Dual magnification design supports 2x optical zoom, precisely capturing high/low edges of stepped workpieces (e.g., steps, grooves), resolving traditional lens “near-clear, far-blurred” issues.

② Hardware Synergy Enhancement: Dual 20-megapixel cameras enable binocular vision, reducing stitching error from ±0.02mm to ±0.005mm; Auto-adjustable multi-angle surface lighting (0-90° range) + custom coaxial illumination achieve 99.5% edge recognition success rate, identifying edges as narrow as 0.005mm.

③ Performance Metrics: Dimensional measurement repeatability ±0.002mm (equivalent to bottom-light standards), AI edge algorithm noise filtering accuracy 98%.

2. Compatible Device Models and Functional Logic

Double-telecentric lens are primarily designed for high-precision specialized measurement equipment (such as models in the image3 series with suffixes like “Pro” or “Precision”), e.g., image3-P, image3-Precision. These devices are core solutions for scenarios requiring micron-level precision, including semiconductor chips, smartphone glass covers, and precision molds.

① Equipment must achieve “distortion-free measurement across the entire field of view.” The low distortion characteristic of double-telecentric lens directly determines the precision baseline of the equipment (e.g., the repeatability accuracy of the image3-P is ≤0.002mm, entirely dependent on the lens's optical error control).

② For step-height inspection on workpieces (e.g., mold cavity step heights), the equipment must simultaneously capture data from both high and low surfaces. The lens's dual magnification capability + step-height field-of-view capability eliminates the need for additional mechanical focusing modules, simplifying hardware structure and enhancing measurement efficiency.

II. 4K HD Zoom Lens

1. Core Optical Performance and Hardware Synergy (Continuing Core Data)

① 4K Resolution + Wide Field of View: 3840×2160 pixels, compatible with 1-inch sensors, high pixel density enabling capture of 0.008mm micro-features; At 1x magnification, field of view spans 150mm × 84mm—22% larger than conventional 4K lenses—reducing stitching requirements for large workpieces.

② Hardware Synergy Enhancement: 12MP camera + latest edge detection algorithm eliminates recalibration after zoom changes, with stability error ≤0.003mm; supports automatic surface light measurement without manual light source adjustment.

2. Compatible Device Models and Functional Logic

The 4K zoom lens primarily supports universal/large-format measurement equipment. These devices are core solutions for “large-scale + batch inspection” scenarios such as consumer electronics enclosures (laptops, tablets) and automotive components (plastic clips):

- The equipment must balance “precision” and “efficiency.” While it does not require the extreme precision of a double-telecentric lens, it must flexibly accommodate workpieces of varying sizes—from small 50mm parts to large 150mm housings. The lens's 0.5-5x motorized zoom capability allows the equipment to adapt to multiple workpiece specifications without lens replacement.

- The wide-field-of-view feature reduces the equipment's reliance on “workbench positioning accuracy” (minimizing the number of movement-based stitching operations). Combined with automatic surface light measurement, this reduces the single-piece inspection time from 3 seconds to 1.5 seconds, meeting the efficiency demands of mass production scenarios.

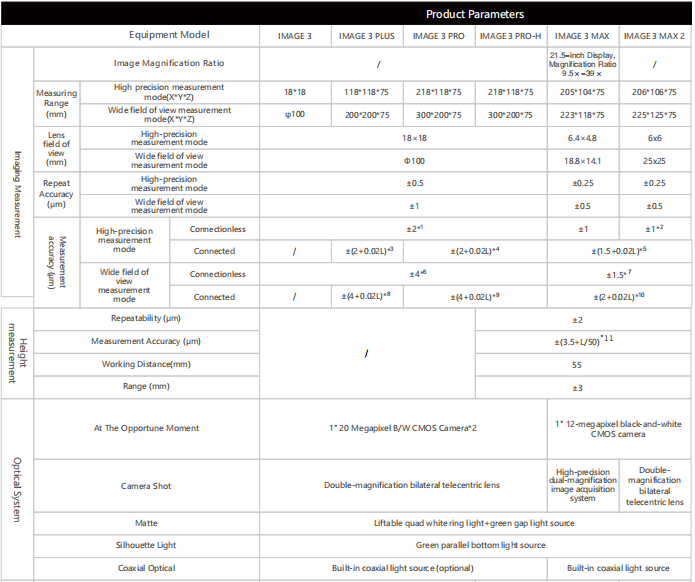

III. Image Dimension Measuring Instrument (Flash Measurement Instrument) Parameter Display

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com