Line scan lenses are imaging systems specifically designed for line-scan cameras. They achieve high-speed, high-resolution imaging through progressive scanning and are widely used in industrial inspection, printing, textiles, electronics, traffic monitoring, and other fields. The classification and differences of line scan lenses are primarily based on their design structure, application scenarios, and performance characteristics.

I. Classification by Optical Structure

1. Telecentric Line-Scan Lens

(1) Features: Utilizes a telecentric optical path design where the principal rays are parallel to the optical axis, eliminating perspective distortion. Image size remains consistent throughout the depth of field, making it suitable for measuring high-precision objects (e.g., chips, precision components). Typically an F-Theta lens, it exhibits extremely low distortion (<0.1%).

(2) Applications: Semiconductor inspection, surface defect detection for 3C products, dimensional measurement. Essential for scenarios requiring strict avoidance of perspective distortion (e.g., diameter measurement of circular objects).

2. Non-telecentric Line-Scan Camera

(1) Characteristics: Standard optical path design with non-parallel primary rays, resulting in perspective distortion. Lower cost but demands stricter control over distortion and aberrations. Suitable for applications insensitive to distortion (e.g., large-format printed material inspection).

(2) Applications: Texture inspection in textiles, paper, wood, etc. Traffic monitoring (license plate recognition, road crack detection).

II. Classification by Focal Length

1. Short-focus Line-Scan Camera

(1) Features: Wide field of view, suitable for inspecting large-format objects (e.g., 1-meter-wide fabric). Shallow depth of field requires precise manual focusing or integration with autofocus systems. Typically lower resolution (due to larger pixel size).

(2) Applications: Large-area inspection in textile, printing, and packaging industries. Panoramic imaging in traffic surveillance.

2. Long-Focus Line-Scan Lens

(1) Features: Small field of view, suitable for high-resolution inspection (e.g., micron-level defects). Deep depth of field, capable of covering objects within a certain height range. Requires high-precision mechanical positioning (e.g., X-Y-Z three-axis stage).

(2) Applications: Semiconductor wafer inspection, PCB board defect analysis. Medical endoscopes (line scan camera + telephoto lens).

III. Classification by Image Sensor Size

1. Close-up Noodles Sweeping the Camera Lens

(1) Features: Compatible with small-format line-scan cameras (e.g., 1K, 2K pixels). Compact and lightweight, suitable for high-speed motion scenarios. Resolution is limited by pixel size (e.g., 5μm pixels).

(2) Applications: High-speed assembly line inspection (e.g., food packaging, pharmaceutical sorting). Robot vision guidance.

2. Big Elephant Noodles Sweeping the Lens

(1) Features: Compatible with large-format line-scan cameras (e.g., 8k, 16k pixels). Requires large-aperture optical components, resulting in higher costs. Offers high resolution, suitable for detecting minute defects (e.g., 0.1mm-level scratches).

(2) Applications: LCD panel inspection, solar cell EL testing. Aerial remote sensing (line-scan pushbroom imaging).

IV. Classification by Wavelength Range

1. Visible Light Scanning Lens

(1) Features: Covers wavelengths from 400 to 700 nm, compatible with standard LED light sources. Low cost, widely applicable.

(2) Applications: Most industrial inspection scenarios (e.g., surface defect detection, barcode recognition).

2. Infrared Sweeping Lens

(1) Features: Covers wavelengths from 700-1000nm or longer, requiring specialized coatings. Suitable for thermal imaging or detecting defects in specific materials (e.g., internal flaws in plastics or glass).

(2) Applications: Agriculture (crop moisture detection), construction (wall leakage detection).

3. Ultraviolet Light Scanner Lens

(1) Features: Covers wavelengths from 200 to 400 nm, requires quartz lenses. Suitable for detecting fluorescent labels or minute particles (e.g., semiconductor impurities).

(2) Applications: Biomedical (cell analysis), environmental monitoring (water quality testing).

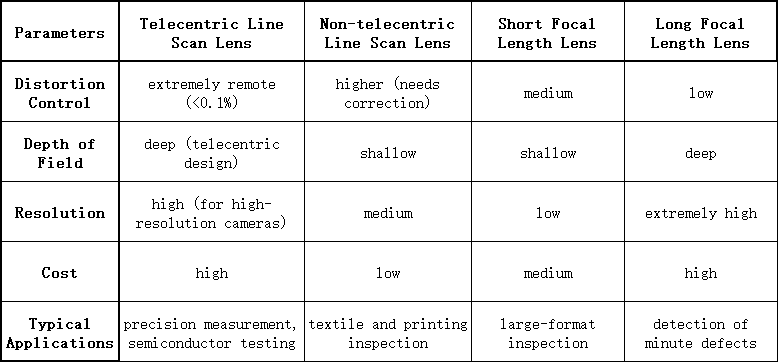

V. Categorical Summary:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com