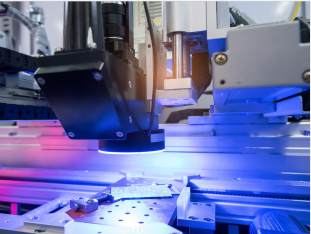

In the era of Industry 4.0, industrial camera vision solutions have emerged as a core driver for manufacturing transformation and upgrading, leveraging their unique technological advantages. Compared to traditional manual inspection or mechanical measurement, vision solutions achieve comprehensive breakthroughs in inspection accuracy, efficiency, and functionality through the “machine's eye,” providing critical support for enterprises to reduce costs and enhance efficiency.

I. Rapid and Precise Detection Capabilities

Industrial cameras capture thousands of frames per second. Combined with high-performance algorithms, they complete target recognition and defect analysis within milliseconds.

II. Eliminating Human Error: Stable, Reliable, and Traceable Data

Manual inspection is susceptible to fatigue, mood, and other factors, resulting in a missed defect rate of 5%-10%. Visual inspection solutions achieve 100% full inspection through standardized algorithms and deep learning models, with results unaffected by environmental interference.

III. Boosting Production Efficiency: 24/7 Continuous Operation, Seamless Integration with Automated Production Lines

The vision system operates 24/7 without interruption and seamlessly integrates with robotic arms, AGVs, and other equipment, enabling full automation of the “inspection-sorting-assembly” workflow.

IV. Enabling Complex Functions: Intelligent Upgrades from Measurement to Decision-Making

Beyond performing fundamental tasks like dimensional measurement and defect identification, the vision solution leverages deep learning to deliver intelligent analysis in complex scenarios.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION