What are the application scenarios for industrial camera vision solutions?

In the wave of smart manufacturing, industrial camera vision solutions have emerged as a key technology for manufacturing upgrades, leveraging their advantages of high precision, high efficiency, and non-contact inspection. Their applications span product quality inspection, dimensional measurement, defect identification, automated sorting, and robotic vision navigation, delivering intelligent solutions for industries including electronics, automotive, and new energy.

I. Product Quality Inspection: Comprehensive Coverage from Micro to Macro Levels

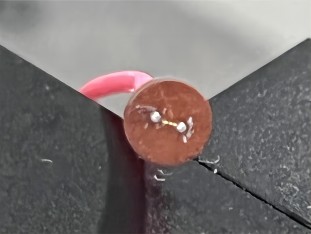

In the electronics manufacturing sector, industrial vision systems can detect minute defects such as cold solder joints on PCBs and misaligned chip pins with micron-level precision. Within the food packaging industry, image comparison technology identifies issues like misaligned labels and improper seals to ensure product compliance.

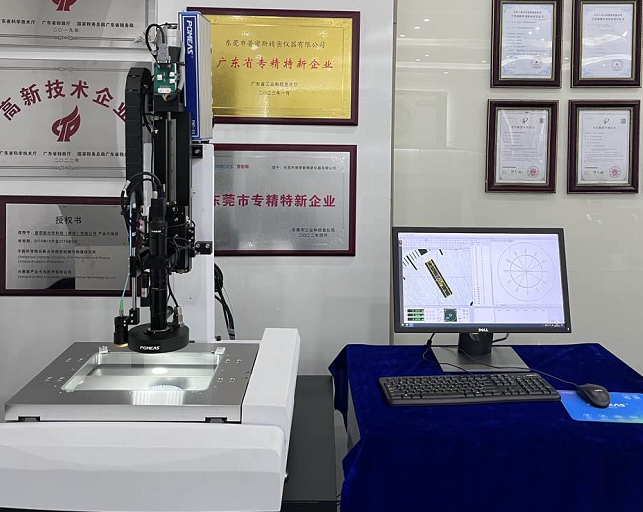

II. Dimension Measurement: Sub-millimeter precision replaces manual calipers

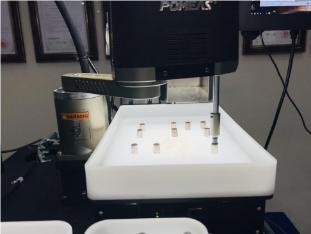

In automotive parts manufacturing, vision systems can rapidly measure critical dimensions such as gear pitch and bearing diameter, achieving measurement speeds over ten times faster than traditional calipers while ensuring data traceability. During semiconductor packaging, vision solutions precisely measure wafer thickness and wire bonding arc height with error control within ±1μm, meeting the demands of advanced manufacturing processes.

III. Defect Identification: Deep Learning Enables Complex Scenarios

Complex texture defects that are difficult for traditional visual solutions to handle—such as scratches on metal surfaces and stains on fabrics—can be efficiently identified using deep learning algorithms.

IV. Automated Sorting: Precision Decision-Making in High-Speed Scenarios

Utilizing a vision system to identify product dimensions or contour information, combined with robotic arms to achieve sorting at a rate of tens of thousands of pieces per hour; on 3C electronics assembly lines, vision-guided robots pick up scattered components to enhance assembly efficiency.

V. Robot Vision Navigation: Intelligent Path Planning in Dynamic Environments

AGVs achieve calibration-free navigation through visual SLAM technology, adapting to complex production line layouts. Collaborative robots equipped with vision modules autonomously identify workpiece positions and orientations to perform precision assembly tasks.

As an industry-leading technology provider, POMEAS offers a full range of industrial cameras, lenses, lighting solutions, and a dedicated deep learning algorithm team. We deliver one-stop solutions spanning hardware selection to software development for sectors including electronics, automotive, and new energy.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com