In modern industrial manufacturing, precise measurement of product dimensions and shapes is critical to ensuring quality and consistency. As automation and intelligence advance, traditional manual or offline measurement methods struggle to meet the demands of efficient production. Online projection measuring instruments have emerged as essential tools for achieving high-precision, high-efficiency dimensional inspection in industrial production processes.

I. Introduction

The online projection measuring instrument is an advanced device specifically designed for real-time measurement and inspection of product dimensions, shapes, positions, and other parameters on industrial production lines. It enables automatic non-contact measurement during the manufacturing process, offering highly efficient and precise in-line inspection capabilities. This equipment not only significantly enhances inspection efficiency but also facilitates production process optimization through instant feedback data, thereby reducing defect rates. It finds extensive application across industries such as precision machinery, electronic components, automotive parts, medical devices, and plastic products.

II. Working Principle

The core technology of the online projection measuring instrument is based on optical projection and image processing. Its working principle primarily involves the following steps:

-

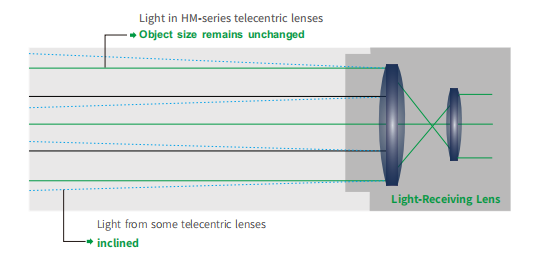

Optical Projection: The device projects the outline of the object under test onto a high-resolution measurement screen or image sensor using a high-brightness light source (such as LED or laser), forming a clear image of the object.

-

Image Acquisition: High-precision sensors (such as CCD or CMOS cameras) capture the projected image and convert it into a digital image signal.

-

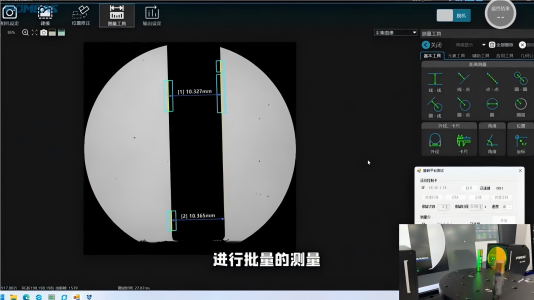

Image Processing and Analysis: Utilizing advanced image processing algorithms, the system performs edge detection, contour extraction, and dimensional calculations to precisely analyze the object's geometric parameters, including length, diameter, angle, and shape deviation.

-

Data Output and Feedback: Measurement results are transmitted in real-time to the control system. They can be displayed via a human-machine interface or integrated with production equipment to enable automated adjustments and quality control.

This non-contact measurement method avoids physical damage to the workpiece, making it particularly suitable for soft, easily deformable, or high-precision components.

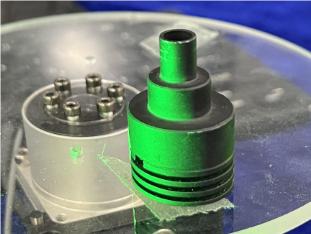

III. Manufacturer Recommendation: POMEAS Online Projection Measuring Instrument HM Series

Among numerous online projection measuring instrument brands, the HM series from domestic brand POMEAS stands out and has gained widespread market recognition. This series offers multiple measurement specifications, covering product measurement needs ranging from 1mm to 120mm, delivering high flexibility and adaptability. The HM series prioritizes stability and user-friendliness in its design, supporting customized configurations to meet specialized measurement requirements across different industries. Offering excellent value for money and comprehensive after-sales service, it stands as one of the top choices among domestic precision measurement equipment.

IV. Key Advantages

Online projection measuring instruments have gained widespread adoption in industrial applications primarily due to the following key advantages:

-

High-Precision Measurement: Utilizing advanced optical systems and algorithms, it achieves micron-level measurement accuracy, ensuring strict control over product quality.

-

Real-Time Online Inspection: Completes measurements instantly on the production line without interrupting processes, significantly boosting production efficiency while enabling full-process quality monitoring.

-

User-Friendly Operation: Typically equipped with intuitive software interfaces, it supports automated operations and quick setup, reducing technical requirements for operators.

-

Stable and Reliable: Robust structural design and premium components ensure consistent performance during extended operation, making it suitable for continuous production environments.

-

Adaptable to Complex Industrial Environments: Features excellent vibration resistance, dustproofing, and interference immunity, enabling stable operation in various demanding industrial settings.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com