What is an image dimension measuring instrument?

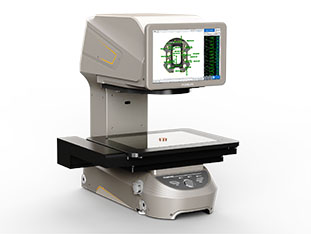

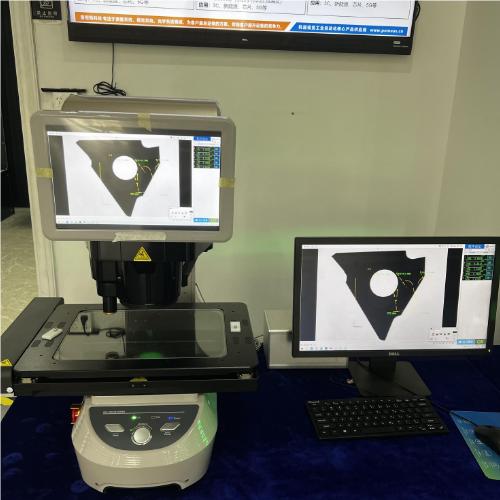

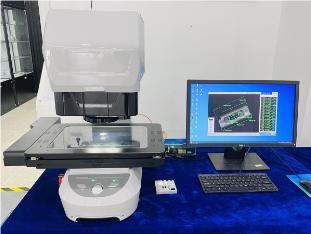

Image Dimension Measuring Instrument is a device that utilizes image processing technology to measure object dimensions. Employing advanced optical imaging technology and intelligent image processing algorithms, it captures object images through high-resolution industrial cameras. Combined with a precision calibration system, it enables rapid and accurate measurement of various component dimensions. This instrument is commonly applied in industrial manufacturing, quality inspection, and other related fields.

How does an image dimension measuring instrument work?

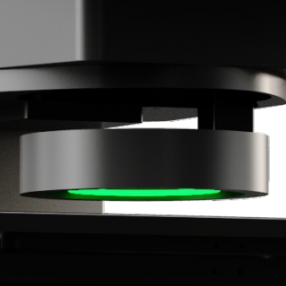

1. High-Precision Imaging System: Equipped with a megapixel-level industrial camera and professional-grade optical lenses to ensure image clarity and detailed reproduction. Its unique coaxial and surface multi-illumination system automatically optimizes lighting based on material properties, eliminating the impact of reflections and shadows on measurements.

2. Intelligent Image Processing Algorithms: Incorporates advanced edge detection algorithms and sub-pixel processing technology to precisely identify the contour boundaries of measurement targets. Even with complex geometries or low-contrast surfaces, the system achieves repeatable measurement accuracy at the ±1μm level.

3. Precision Calibration and Compensation Mechanism: System calibration utilizes standard calibration plates, while advanced techniques like temperature compensation and optical distortion correction ensure measurement stability across varying environmental conditions. Auto-focus functionality guarantees measurement consistency across different height planes.

In what scenarios is an image dimension measuring instrument suitable for use?

1. Precision Parts Batch Inspection: During the production of connectors, miniature bearings, precision gears, and similar components, the IMAGE 3 series enables rapid batch measurement, simultaneously inspecting multiple dimensional parameters in a single pass to significantly boost inspection efficiency.

2. Automated Production Line Integration: As a vital component of smart factories, this system seamlessly integrates with robotic arms, conveyor belts, and other equipment to perform real-time in-line measurements. It promptly identifies production deviations, enabling closed-loop quality control management.

3. Research Laboratory Applications: In fields like materials science and micro/nano manufacturing, researchers leverage its high-precision measurement capabilities for microscopic dimensional analysis, providing reliable data support for scientific work.

4. Quality Control Enhancement: Traditional manual sampling inspection suffers from low efficiency and inconsistent results. The IMAGE 3 series enables fully automated, 100% inspection modes, establishing a comprehensive quality data traceability system.

What are the advantages of an image dimension measuring instrument?

1. Exceptional Measurement Performance

-

Ultra-high precision: Measurement accuracy up to ±1μm, meeting the most stringent industrial standards

-

Rapid response: Single measurement time of just 0.5–2 seconds, significantly boosting inspection efficiency

-

Wide-range adaptability: Supports measurement ranges from 0.1mm to 300mm, covering the vast majority of industrial part dimensions

2. Intelligent Operating System

-

Intuitive Interface: Graphical user interface supporting one-click measurement, requiring no specialized training to operate

-

Smart Recognition: AI-assisted identification function automatically distinguishes between qualified and unqualified products

-

Data Management: Comprehensive measurement data storage, analysis, and report generation capabilities

3. Robust System Compatibility

-

Flexible Configuration: Customizable optical systems, workstations, and software functions tailored to customer requirements

-

Open Interfaces: Supports multiple communication protocols for seamless integration with MES, ERP, and other systems

-

Highly Expandable: Optional add-ons include 3D measurement modules, automated loading/unloading systems, and other expansion capabilities

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com