I. What Is a Double-Telecentric Lens?

The double-flush-center lens is a high-end industrial lens that eliminates parallax and achieves constant magnification through specialized optical design. Its core principle involves placing aperture diaphragms at both the object-side and image-side focal planes, ensuring that the principal rays from both sides remain parallel to the optical axis. This design maintains a constant image height regardless of object distance, thereby completely resolving measurement errors caused by perspective distortion in traditional lenses.

Key Technical Breakthroughs:

1. Dual telecentric structure: Symmetrical design of the front group (positive focal length lens group) and rear group (negative focal length lens group), combined with a centered aperture, achieves dual telecentricity for both the object side and image side.

2. Aspheric Compensation Technology: Incorporates even-order aspheric surfaces on critical elements to counteract positive distortion generated by the front group.

3. High-Refractive-Index Glass Application: The front group employs high-refractive-index glass to compress beam deflection angles, while the rear group utilizes low-dispersion glass to minimize chromatic aberration's impact on high-frequency details, ensuring MTF remains no less than 0.3 at 100 lp/mm frequency.

II. Classification and Selection Logic of Telephoto Lenses

Telecentric lenses are further categorized into object-side telecentric lenses, image-side telecentric lenses, and dual telecentric lenses. The following selection logic is provided based on visual inspection requirements:

1. Object-side telecentric lenses dominate the industrial inspection field (accounting for over 90%) as they directly resolve perspective distortion issues where “near objects appear larger than distant ones.” For instance, when inspecting objects with height variations, standard lenses require multiple calibrations, whereas object-side telecentric lenses enable “readings directly from the image.”

2. Dual-side telecentric lenses, due to their high cost (2-3 times the price of object-side telecentric lenses), are reserved for scenarios demanding extreme precision. Examples include semiconductor wafer inspection, where both micron-level circuit patterns and geometric dimensions must be captured simultaneously.

III. Application Case Analysis of Double Telecentric Lenses

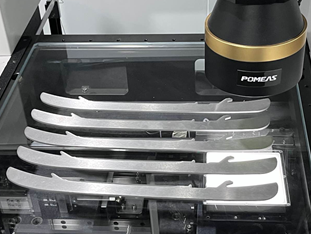

Case 1: Ice Skating Blade Size Measurement

-

Challenge: The blade edge thickness of ice skates is only 0.5mm, and parameters such as edge straightness and curvature must be inspected. Traditional lenses suffer from insufficient depth of field, resulting in blurred edges.

-

Solution: Utilized the POMEAS LTDC01607-120(Y) double-side telecentric lens with a working distance of 120mm and a depth of field of 0.02mm, achieving micron-level resolution. Through coaxial illumination design (point light source + beam splitter prism), it enables clear imaging of surface pits and burrs.

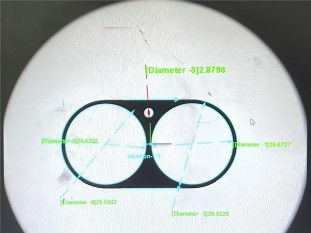

Case 2: Mobile Phone Camera Module Dimension Measurement

-

Challenge: Camera module lenses are 3mm thick, requiring measurement of parameters such as lens spacing and aperture diameter. Traditional lenses cause measurement errors exceeding 10μm due to distortion.

-

Solution: Utilized the POMEAS LTDC01607-120(Y) double-sided telecentric lens with 1μm resolution. Through a “fixed object-image distance + symmetrical light-focus distribution” design, magnification fluctuation was controlled within ±0.01%.

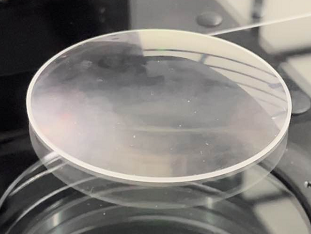

Case 3: Lens Profile Dimension Measurement

- Challenge: Progressive multifocal lenses feature continuously varying surface curvature. Traditional lenses suffer from limited field of view, necessitating multiple image stitching processes, resulting in low efficiency.

- Solution: Utilize the POMEAS LTDC01607-120(Y) dual-side telecentric lens paired with a high-definition 10-megapixel industrial camera to achieve single-shot imaging coverage of the entire lens. Through a “front-group focal length extension” design (first lens element with a curvature radius of 200mm), the working distance is extended to 150mm, preventing contact between the lens and the lens element.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com