In modern industrial production, efficient and precise product sorting is a critical factor in enhancing production efficiency and quality. Traditional manual sorting methods are not only inefficient but also susceptible to human error, resulting in inconsistent sorting accuracy. With the rapid advancement of automation technology, automated sorting systems integrating advanced sensors and intelligent robotic arms are increasingly becoming the industry standard.

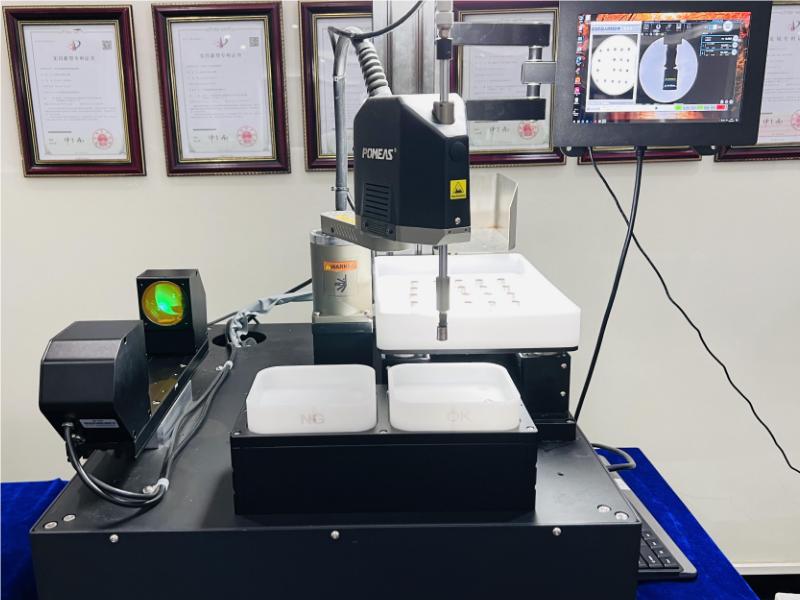

1. System Composition:

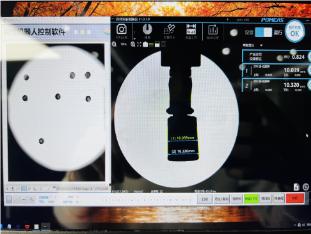

(1) Telecentric Measurement System: Serving as the system's “eyes,” it rapidly and accurately measures critical product parameters such as dimensions and shape, while simultaneously determining product qualification in real time (OK/NG).

(2) SCARA Robot Arm: Acting as the system's “arm,” it executes actions such as grabbing and placing based on feedback from the Telecentric Measurement System, enabling automatic product sorting.

(3) Control System: Coordinates the operations of the Telecentric Measurement System and SCARA robot arm to ensure the entire sorting process runs smoothly.

2. Working Principle:

(1) Sample Grasping: The SCARA robot precisely grasps products awaiting sorting according to a pre-programmed sequence.

(2) Data Measurement: The robot places the picked product onto the measurement platform of the Telecentric Measurement System. The system completes product data measurement within 35 milliseconds and instantly determines product qualification.

(3) Sorting and Placement: Based on feedback from the Telecentric Measurement System, the SCARA robot places qualified products into the OK collection bin and non-qualified products into the NG collection bin, achieving automated product sorting.

3. Performance Advantages of Telecentric Measurement Systems:

(1) High-Speed Measurement: The Telecentric Measurement System delivers rapid measurement capabilities at 35ms, significantly enhancing sorting efficiency on production lines.

(2) Precise Determination: Utilizing advanced image processing algorithms, the system accurately measures critical product parameters such as dimensions and shape, while instantly determining product compliance to ensure sorting accuracy.

(3) Real-Time Feedback: The measuring instrument communicates in real time with the control system, promptly relaying measurement results and classification decisions to the SCARA robot arm. This enables automation and intelligent operation throughout the sorting process.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION