What are the common types of light sources used in machine vision?

In machine vision systems, the light source is one of the core factors affecting image quality, detection accuracy, and stability. Selecting the appropriate light source type can significantly enhance contrast, reduce noise, and adapt to different materials, shapes, and inspection requirements.

1. Ring Light

① Features: Circular arrangement with uniform light distribution and bright central illumination.

② Applications: Inspection of flat or slightly raised surfaces, such as PCB solder joints, metal scratches, and bottle mouth seals.

③ Selection: White for general use, red for penetrating transparent objects, blue for enhancing metal details; inner diameter should be slightly larger than the test object.

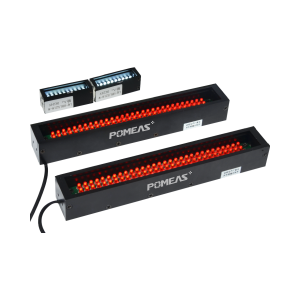

2. Linear Light Source

① Features: Linear array configuration, directional illumination, supports multi-side combinations.

② Applications: Inspection of elongated objects or localized areas, such as battery tabs, paper edge damage, and character recognition.

③ Selection: Ensure length covers the detection area; low-angle (15°–30°) illumination highlights edges.

3. Flat Light Source

① Feature: Light source positioned behind the object, with light transmission creating high-contrast outlines.

② Applications: Detection of transparent or translucent objects, such as glass thickness measurement, LCD screen defect inspection, and aperture measurement.

③ Selection: High-brightness LED arrays are suitable for high-speed inspection lines, while diffusion plates reduce light spots.

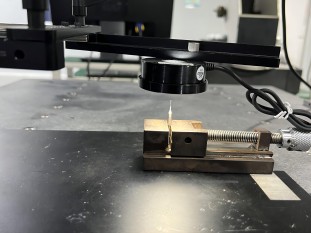

4. Coaxial Light Source

① Features: Light rays are collinear with the camera's optical axis and enter perpendicularly, eliminating reflections.

② Applications: Inspection of highly reflective surfaces, such as scratches on phone casings, glass cracks, and gear tooth surfaces.

③ Selection: High-transmission beam splitters paired with high-power LEDs for high-speed inspection.

5. Point Light Source

① Features: Compact high-brightness light source with concentrated illumination.

② Applications: Inspection of minute areas such as chip pins, solder joint defects, and precision measurements.

③ Selection: Long-life LEDs (50,000+ hours) with fiber optic coupling for extended-range illumination.

6. Dome Light Source

① Features: Hemispherical diffuser provides uniform light coverage across curved surfaces.

② Applications: Inspection of complex-shaped objects such as automotive dashboards, surface damage on fruits, and tablet indentations.

③ Selection: High-transmittance diffuser; adjust installation height to match curvature.

7. Combination Light Source

① Features: Multi-light source combinations (e.g., ring + bar) adapt to complex scenarios.

② Applications: Detection of reflective and transparent objects, such as automotive connectors and multi-process pharmaceutical packaging.

③ Selection: Design customized combinations after defining detection targets; supports synchronized trigger control.

General Principles:Prioritize contrast while maintaining uniformity; Select based on spatial and cost considerations; Verify optimal solutions through experimentation.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com