How does metallographic microscopy reveal microcracks, hole wall tears, and plating voids in PCB?

Testing Background:

Printed circuit boards (PCBs) serve as the core structural components of electronic devices, with the integrity of their microscopic internal structures directly determining device reliability. Common defects such as microcracks, hole wall tears, and plating voids are typically micrometer-scale, concealed within the substrate or hole walls. Conventional inspection methods struggle to accurately identify these flaws, yet they can trigger critical failures like signal anomalies and short circuits.

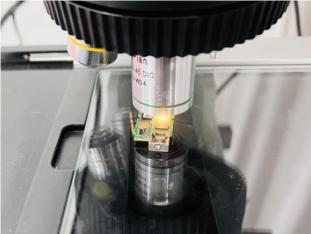

Solution: POMEAS Metallographic Microscope

Metallographic microscopes, with their high magnification capabilities ranging from 500X to 1000X, clearly reveal the morphology and distribution of various microscopic defects, making them indispensable core equipment in PCB quality inspection.

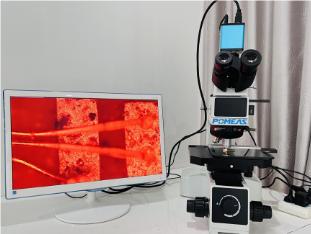

For resin microcracks, high magnification clearly reveals linear dark fissures measuring 1-5 micrometers, precisely identifying their initiation points and propagation directions—a level of localization and analysis unattainable through low magnification or ultrasonic testing. For hole wall tears and drilling burrs, 1000X magnification clearly reveals the jagged morphology of torn glass fibers, enabling identification of burr material and dimensions. This provides direct evidence for optimizing drilling processes, outperforming low-magnification optical observation and X-ray inspection.

During chemical copper plating and electroplating processes, metallographic microscopes can precisely capture latent defects such as discontinuities and pinholes in the copper deposit layer, as well as circular voids measuring 2–8 micrometers within the plating layer. They can also correlate these defects with their root causes (e.g., aged copper plating solution, uneven current distribution). Conventional conductivity testing or ultrasonic scanning can only assess macro-level compliance, failing to visualize or trace microscopic defects.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION