Spectral Sensor Application for Transparent Object Thickness Measurement

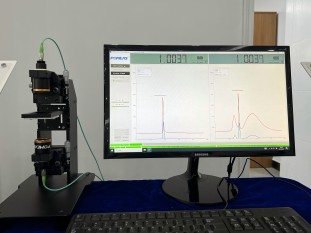

For measuring the total thickness and layer thickness of transparent materials (glass, film), spectral confocal technology achieves high-precision, non-contact detection through various configuration solutions.

I. Single-Point Solution: Thickness Measurement Based on Refractive Index Compensation

1. Technical Principle: The single-side single-point solution emits polychromatic light through a single probe. Leveraging the “wavelength-displacement linear mapping” characteristic of spectral confocal imaging, it captures the characteristic wavelengths of reflected light from the upper and lower surfaces of transparent objects. Combined with material refractive index calculations, this determines the total thickness. The core formula is: D = 2⋅Δλ/ΔD(λ2 − λ1)⋅n

Where λ1 and λ2 represent the wavelengths of reflected light from the upper and lower surfaces, respectively; n denotes the material refractive index; and Δλ/ΔD is the sensor wavelength-displacement calibration coefficient.

2. Key Advantages:

(1) Non-contact measurement: Eliminates damage to flexible films caused by contact tools (e.g., micrometers), particularly suitable for ultra-thin materials (e.g., 50μm PET film);

(2) Single-side operation: Requires illumination from only one side, suitable for enclosed spaces or inaccessible scenarios (e.g., internal structure inspection of mobile phone screens);

(3) High precision: Resolution up to 0.1μm, meeting the curved glass thickness tolerance requirement of ≤±10μm in the 3C electronics industry.

3. Typical Application Scenarios: Single-layer glass thickness inspection, film layer thickness monitoring.

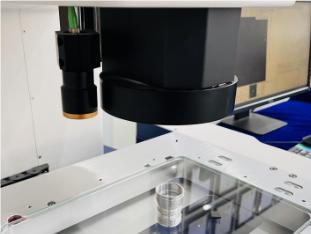

II. Bilateral Synchronous Approach: Absolute Thickness Measurement Based on Optical Path Difference

1. Technical Principle: The bilateral synchronous approach employs two sensors positioned opposite each other to measure the propagation path lengths of light through the upper and lower surfaces of a transparent object. The geometric thickness is directly calculated from the optical path difference using the formula: D = (L₂ − L₁)/2. Here, L₁ and L₂ represent the distances from each sensor to the upper and lower surfaces, respectively. This method does not rely on refractive index and achieves nanometer-level precision.

2. Key Advantages:

(1) Absolute Accuracy: Eliminates refractive index errors, particularly suitable for high-refractive-index materials (e.g., sapphire, n=1.77) or composite materials (e.g., glass + ceramic coating).

(2) Dynamic Measurement: Supports high-speed object detection, such as thickness fluctuation monitoring during semiconductor wafer transport.

(3) Wide Coverage: Expands the measurement area through XY-axis motion platforms, enabling full inspection of large transparent objects (e.g., display panel glass).

3. Typical Application Scenarios: Semiconductor wafer thickness inspection, aerospace transparent component inspection.

III. Selection Recommendations

- For detecting single-layer glass or multilayer films with known refractive indices under budget constraints, prioritize the single-side single-point solution.

- For measuring high-refractive-index materials, composites, or large transparent objects with stringent accuracy requirements, the dual-side simultaneous solution is the optimal choice.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com