Introduction to the Implementation Process of Machine Vision System Inspection Project

With the popularization of enterprise automation application, more and more enterprises need to customize the solution of machine vision system. How to introduce the scheme and implementation of machine vision system smoothly? Enterprises themselves should have some knowledge of the design and production process of machine vision detection system. Today, the whole machine vision detection system is still at an early stage.

The whole process from product inspection and evaluation to visual system design is briefly introduced.

1. Pre-project evaluation

A. Tell us about our vision project needs by telephone or online customer service. The company will have professional project engineers to communicate with you initially and understand your needs in detail and in depth.

B. We need you to provide test samples (OK products and various NGs) and the scene environment. If not for the whole machine, we also need to provide the installation space of visual equipment and peripheral IO communication. If necessary, the project engineer can also come to your company for on-site evaluation.

C. According to the samples provided, the project engineer will make a preliminary technical evaluation in the company. Generally, the test results will be given within 2 to 3 working days after receiving the samples.

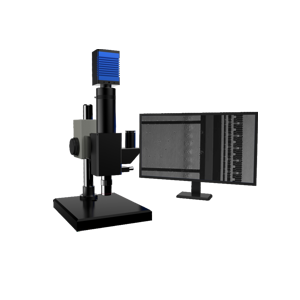

D. The project engineer will give you professional advice based on the test results. Provide appropriate visual products (including industrial cameras, lenses, light sources, computers, machine vision system software selection, etc.) to you, and then provide you with preliminary plans and project cost estimates after the test results come out.

E. If you have any questions about the plan, you can contact the project engineer at any time. The project engineer will answer your questions and improve the plan to meet your needs.

2. Project Establishment

After the preliminary evaluation of the project, both sides confirm the feasibility of the project plan. The project engineer will then establish a new project process to proceed.

3. Clear Test Standards

Need you to collect OK products and limited NG products (that is, the preliminary testing of NG varieties that can be detected), need a certain number. The project engineer will test the samples provided by you and confirm the detailed testing standards with you.

4. Recognition of other matters

After defining the testing standard, the project engineer will further confirm with you that the testing equipment meets the requirements of installation site, machinery and electricity. If your company has special requirements for the use of equipment, please submit them in time for our evaluation and design.

5. Production of overall proposal, detailed quotation sheet and contract

According to the above confirmation, the project engineer makes a detailed overall plan, which includes the whole machine drawing, visual system configuration, testing standards, software functions and so on.

Design and Manufacturing Process of Machine Vision System Solution

After signing the contract and all aspects of financial confirmation, further design and manufacture of system equipment will generally go through the following stages:

1. Provide relevant samples

It is necessary to provide samples of good and bad products in different degrees, appearance dimensions of product samples and design tools. If you need to use special vehicles, please provide the relevant dimensions of special vehicles for our design.

2. Confirmation of Equipment Layout and Electrical Control Action Flow

After several working days of receiving the relevant samples you provided, we will provide the equipment layout and electrical control action flow to your company's responsible person for confirmation. If you have any questions, you can communicate with the company's technical engineer, and the technical engineer will solve your problem as soon as possible.

3. Design of Machine Parts Drawing

After the confirmation of the layout of the whole machine, the design of the mechanical parts is carried out.

4. Selection of Mechanical and Electrical Standard Parts

After confirming the layout of the whole machine and the operation flow of the electronic control system, the selection of mechanical and electrical standard parts will be completed.

5. Material Purchasing and Parts Processing

Material procurement, all channels in accordance with the normal process, strictly ensure product quality, complete material procurement and parts processing.

6. Design of Visual and Electronic Control Software

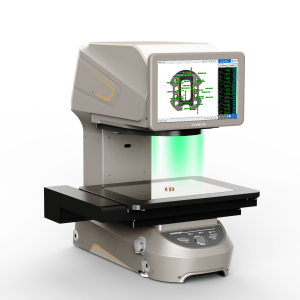

In the aspect of visual software design, the software has accurate positioning, stable and reliable algorithm, friendly interface, beautiful appearance, simple operation, convenient parameter adjustment. When the software reaches the detection ability, the detection time will be reduced to the minimum and the adjustment will be reduced to the minimum.

7. Assembly and trial operation of the whole machine

After each part has passed the inspection, it is transported to the assembly site for assembly. The whole assembly process is strictly in accordance with the requirements of the drawings for mechanical and electrical installation, without neglecting every detail. After assembling, the machine runs empty and runs in the moving parts.

8. OK/NG Sample Testing

After a period of air operation, OK/NG samples are tested, and the electronic control action of the test equipment is tested. Will the mechanism cause secondary damage to the product, and whether the software testing is accurate and stable? When all the above tests meet the requirements of the contract, the pre-acceptance before shipment can be carried out.

The last step is the delivery of machine vision equipment, on-site mechanical installation, image effect debugging, visual inspection software debugging, electrical debugging, maintenance personnel training and production, equipment maintenance and use instructions and other steps, such as a system of visual inspection program process is these, I hope this paper can help you.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com