As the gaming industry continues to evolve, the design, functionality, and user experience of game controllers—as critical input devices—are receiving increasing attention. Multisensor measurement systems, serving as high-precision, multifunctional measurement tools, play an increasingly vital role in evaluating game controllers. However, due to the complexity and unique characteristics of game controllers, these measurement systems also encounter certain technical challenges during the measurement process.

Project Challenges and Solutions

1. Capturing Complex Structures and Details: Game controllers typically feature intricate structural designs and rich detail characteristics, such as buttons, joysticks, and touchpads. These components not only vary in shape but also exhibit fine dimensions, demanding measurement systems with extremely high resolution and precision to accurately capture every detail of the controller.

2. Material Properties and Surface Treatments: Controller casings utilize diverse materials including plastic, rubber, and metal, each exhibiting distinct optical characteristics and surface reflectivity. Additionally, surfaces may undergo specialized treatments like anti-slip textures or coatings, all of which impact measurement accuracy. Consequently, the measurement system must adapt to varying material properties to ensure stable results.

3. Dynamic Performance Measurement: During use, components like buttons and joysticks undergo frequent movement. To comprehensively evaluate controller performance, parameters such as displacement, velocity, and acceleration must be measured under dynamic conditions. This demands high-speed, high-precision dynamic measurement capabilities from the system.

Application Optimization

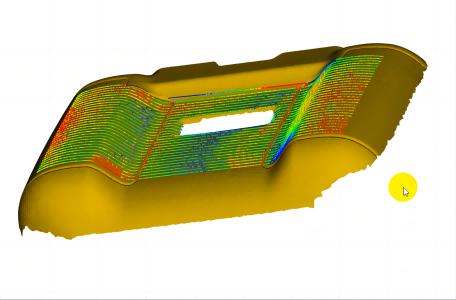

1. Design and Optimization Support: By capturing the three-dimensional model and data of the game controller through a multi-sensor measurement system, designers gain a more intuitive understanding of the controller's structure and details, enabling targeted optimization and improvements. For instance, adjustments can be made to button layouts, grip ergonomics can be enhanced, and joystick sensitivity can be refined to elevate user experience and gaming performance.

2. Quality Control and Product Inspection: During production, multi-sensor measurement systems enable rapid, accurate quality control and product inspection of game controllers. By comparing measured data against design specifications, issues in the manufacturing process can be promptly identified, ensuring consistent and stable product quality.

3. Customization and Personalization Services: As personalized demands grow, customized controller services are gaining traction. Multi-sensor measurement systems provide precise data support for these services, enabling users to tailor unique controllers based on their preferences and requirements.

With continuous technological advancements and system optimizations, these challenges will gradually be overcome. In the future, the POMEAS Metric multi-sensor measurement system will play an increasingly vital role in the design, production, quality control, and personalized services of game controllers, driving the sustained development and innovation of the game controller manufacturing industry.

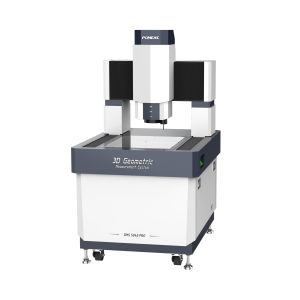

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com