Image dimension measuring instrument for measuring mobile phone mid-frame molds?

I. Core Technology Support: The “Precision Confidence” of the Measuring Instrument

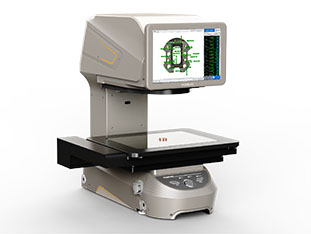

The image dimension measuring instrument meets the high-precision measurement demands of smartphone mid-frame molds by relying on two core technological foundations: a high-precision visual acquisition module and an intelligent algorithm processing system.

1. The high-precision visual acquisition module comprises a megapixel industrial camera, high-resolution optical lens, and LED ring light. It clearly captures micron-level details on mold surfaces, preventing blurred imaging caused by light reflection or complex textures.

2. The intelligent algorithm processing system integrates edge extraction, image stitching, coordinate calibration, and other algorithms. It converts captured 2D images into precise numerical data, enabling quantitative analysis of parameters such as dimensions, angles, and radii. With a product accuracy of up to 1.5μm, it perfectly aligns with the core logic outlined in the syllabus: “Acquiring mold dimensional data through image processing technology.”

II. Measurement Challenges and Compatibility Issues with Smartphone Midframe Molds

As the “skeleton” of the entire device, the mold for a smartphone's midframe must meet extremely high precision requirements—such as controlling frame thickness tolerances within ±0.01mm and limiting camera hole center offset to no more than 0.02mm. It must also accommodate complex shapes like curved frames and chamfered radii. Traditional contact measurement methods (such as calipers and micrometers) are not only inefficient but also risk scratching mold surfaces. They struggle to accurately measure complex dimensions like curved surfaces and hole depths. In contrast, the non-contact measurement approach of image dimension measurement instruments avoids physical damage to molds. Through rapid imaging and algorithmic analysis, it simultaneously covers critical dimensional and shape inspections, addressing the pain points of traditional measurement: slowness, limited accuracy, and susceptibility to damage.

III. Specific Application Workflow: The Full Path from Imaging to Data Analysis

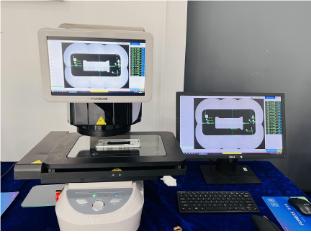

- Mold Positioning and Calibration: Secure the mobile phone mid-frame mold onto the high-precision workbench of the measuring instrument. Utilize the reference point calibration function to establish the measurement coordinate system—typically using the mold's reference holes and edge contours as benchmarks. This ensures measurement data consistency and prevents errors caused by placement deviations.

- Visual Acquisition and Image Preprocessing: Activate the industrial camera and capture two-dimensional images of the mold using multi-angle illumination from a ring light. The software automatically performs noise reduction and enhancement processing to highlight critical features such as mold edges, hole positions, and grooves, laying the foundation for subsequent dimensional extraction.

-

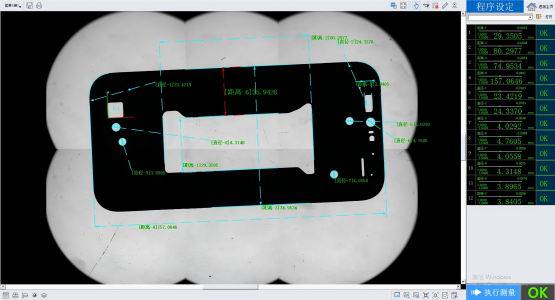

Key Parameter Measurement and Analysis: Based on preprocessed images, the algorithm automatically identifies and measures core parameters across three dimensions:

- Linear dimensions: Frame width, thickness, hole diameter, spacing between adjacent holes, etc.;

- Shape accuracy: Chamfer radius, surface profile, flatness (to prevent mold deformation causing poor mid-frame alignment);

- Positioning accuracy: Offset between holes and frame edges, symmetry of grooves, etc.

Upon completion of the measurement, the system automatically generates a data report, clearly indicating the acceptable range and providing an intuitive visualization of whether the mold meets production standards.

- Batch Inspection and Data Traceability: For mass-produced mobile phone frame molds, the measuring instrument supports automated batch inspection. The workbench automatically switches mold positions, eliminating manual repositioning. Simultaneously, all measurement data is stored and exported in real time, facilitating subsequent quality traceability and process optimization.

IV. Application Advantages: Empowering Efficient Production of Smartphone Mid-Frame Molds

1. High-Precision Matching Requirements: Product accuracy reaches 1.5μm, far exceeding the micron-level tolerance requirement of ±0.01mm for smartphone frame molds. This offers significant advantages over traditional measurement tools (typically with accuracy above ±0.01mm).

2. Efficient Production Capacity Boost: Single-mold measurement takes only seconds, achieving 5-10 times higher batch inspection efficiency than contact-based measurement, thereby shortening production cycles.

3. Non-contact, damage-free operation: Eliminates friction and pressure between measurement tools and mold surfaces, safeguarding mold precision and reducing scrap rates.

4. Intelligent accessibility: Fully automated operation requires no specialized measurement personnel, minimizing human error. Intuitive data reports facilitate rapid decision-making by production managers.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com