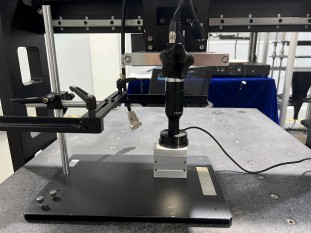

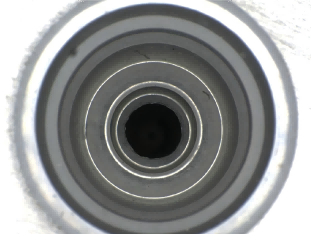

360° lens to detect scratches and contaminants on the inside of aluminum parts

Measurement background:

During the manufacturing process of aluminum part bore, the quality control of the inner wall is crucial. However, there are often problems that affect the quality of aluminum parts, such as the presence of debris residues and scratches generated during the manufacturing process. These imperfections not only affect the appearance of the aluminum part, but may also have a negative impact on its performance in subsequent use. Traditional inspection methods are often difficult to detect these problems on the inner wall in a comprehensive and accurate way, so a more efficient and accurate inspection solution is needed.

Measurement Program:

360° Inside Lens

The 360° interior lens is one of the core components of this inspection solution. It provides full coverage of the inside of the aluminum part, leaving no dead space. This omni-directional view makes it possible to capture scratches and contaminants wherever they occur on the inside of the wall. Compared to traditional linear lenses, the 360° lens greatly improves the comprehensiveness of the inspection and avoids missing problems due to the limited scope of the inspection.

Ring light source

The ring light plays a key role in this inspection program. It surrounds the lens and provides uniform, sufficient light to the inside of the aluminum part. When inspecting the inside of an aluminum part, good lighting conditions are an important prerequisite for obtaining a clear image. The ring light effectively avoids shadows and ensures that scratches and impurities are clearly visible in the image. By adjusting the brightness, color and other parameters of the ring light source, the quality of the image can also be further optimized to improve the accuracy of the inspection.

High Definition Mega Camera

The HD Mega Camera is responsible for recording the images captured by the 360° interior lens in high resolution. Its megapixel-level imaging capability is capable of capturing extremely small scratches and contaminant particles on the inside of aluminum parts. This high-resolution image not only helps inspectors visualize the condition of the interior wall, but also provides a wealth of detail when the image is analyzed at a later stage. For example, image analysis software allows precise measurement of parameters such as the length and width of scratches and the size of impurities, thus providing accurate data to support quality assessment of aluminum parts.

Detecting effects:

The combination of a 360° interior lens, a ring light source and a high-definition megapixel camera creates a complete and efficient solution for detecting scratches and contaminants on the inside of aluminum parts. This solution ensures that the quality of aluminum parts meets high standards and improves the quality control of the entire aluminum manufacturing process.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com