Detection background:

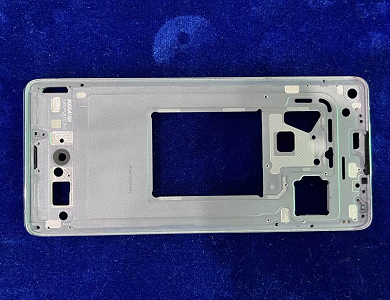

With the popularity of smartphones and the intensification of market competition, the flatness of mobile phone backplanes has become one of the key factors affecting product quality and user experience. Mobile phone backplanes not only need to have good appearance and texture, but also need to ensure that their flatness meets strict manufacturing standards to ensure the stability and reliability of mobile phones during assembly and use. Therefore, it is particularly important to accurately inspect the flatness of mobile phone backplanes.

How can I test the flatness of a mobile phone backplane?

Inspection of the flatness of mobile phone backplanes usually relies on high-precision measurement techniques and equipment. Traditional inspection methods may include the use of contact measurement tools such as micrometers, vernier calipers, etc. However, these methods are not only cumbersome to operate, but may also cause scratches or deformations on the surface of the backsheet due to the measuring force, which may affect the accuracy of the measurement results.

To overcome these limitations, non-contact measurement methods are commonly used in modern manufacturing industries, with line laser profile scanning technology being favoured for its high accuracy, efficiency and non-destructiveness.

Inspection programme: Line laser profile scanning programme

At the heart of the line laser contour scanning solution is the line laser sensor. The sensor calculates contour information on the surface of the backplate using the principle of triangulation by emitting a thin laser line to the surface of the backplate of the mobile phone and receiving the reflected light back.

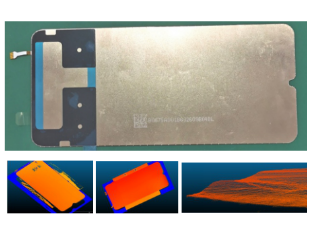

In a specific implementation, the back plate of the mobile phone is placed on a measuring platform, and the line laser sensor moves along a predetermined path to fully scan the back plate. The data collected by the sensor is processed to generate a three-dimensional contour map of the surface of the backplane, thereby visually displaying the flatness of the backplane.

By comparing the preset flatness criteria, it is possible to determine whether the backsheet is qualified or not. In addition, the line laser contour scanning technology can also be used to detect other defects on the surface of the backsheet, such as scratches, dents, bumps, etc., providing comprehensive data support for quality control.

Rendering:

The line laser profile scanning solution has become an ideal choice for flatness inspection of mobile phone backplanes due to its advantages of high accuracy, high efficiency and non-destructiveness. The solution not only improves the inspection efficiency and accuracy, but also reduces the inspection cost, providing strong technical support for quality control in mobile phone manufacturing.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com