I. Key Parameters of Motorized Zoom Lenses

Motorized zoom lenses are core machine vision components that automatically adjust focal length and magnification by driving internal optical elements via motors. Unlike manual zoom lenses, their key advantages lie in automated control, remote operation, and high precision repeatability, enabling seamless integration into automated production lines. Critical parameters are essential for automation applications:

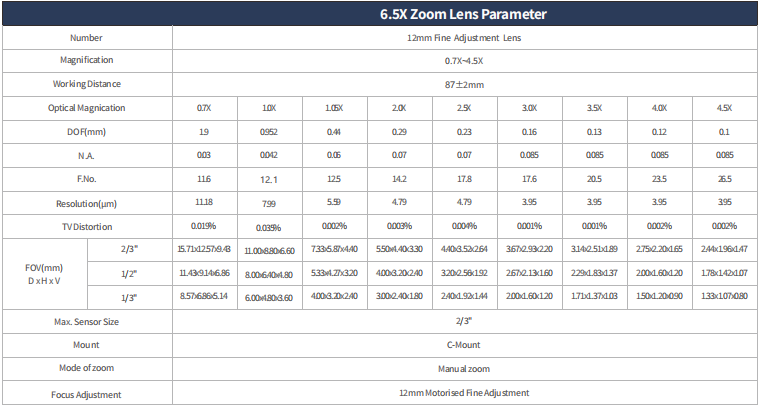

1. Zoom Ratio: Typically 4x, 6x, or 10x (e.g., 10-100mm focal length corresponds to 10x zoom), determining the field of view adjustment range to accommodate inspection of workpieces of varying sizes;

2. Resolution: Must match industrial cameras (e.g., a 2-megapixel lens pairs with 2-5 megapixel cameras) to ensure detailed clarity in automated inspection;

3. Working Distance (WD): Mainstream range 50mm–2000mm, requiring design based on production line space constraints;

4. Response Speed: Motor-driven response time ≤0.5s, meeting high-speed automated production lines (e.g., SMT placement line inspection rhythm of 1–2 workpieces per second).

II. Application Scenarios in the Automation Industry

1. SMT Component Inspection: Before and after reflow soldering, the motorized zoom lens automatically switches magnification levels via PLC or machine vision system control. Low magnification (e.g., 1x) rapidly locates the overall PCB position, while high magnification (e.g., 10x) inspects alignment of 01005 micro-component pads and solder ball defects. This replaces manual focusing, boosting inspection efficiency by over 3 times.

2. Semiconductor Packaging Inspection: For IC chip wire bonding, the lens switches within 2-5 seconds from “wide-angle observation of the bonding area” to “telephoto magnification of wire diameter (≤20μm) and solder joint integrity.” Precision repeatability reaches ±0.01mm, eliminating manual adjustment errors.

3. Component dimension measurement: For precision parts like bearings and gears, the lens integrates with vision measurement software to automatically switch magnification for “rough overall dimension measurement (low magnification) + precise pitch/aperture measurement (high magnification)”, achieving ±0.005mm accuracy. This replaces traditional calipers and reduces manual measurement errors.

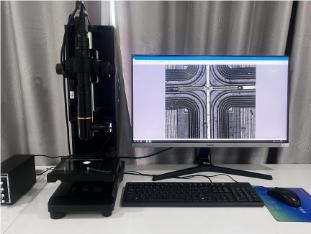

POMEAS, as a leading domestic brand, offers products spanning a 0.58X-14X zoom range. Its 6.5X motorized zoom rail lens innovatively integrates an electric rail system, enabling automated adjustment of inspection positions in the field of robot vision.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION