What are the high-precision measuring instruments used to inspect product dimensions?

In the field of precision manufacturing and quality control, the core instrumentation and equipment used for high-precision measurement of product dimensions primarily includes the following categories, covering solutions ranging from basic to high-end.

I. Mainstream High-Precision Measurement Equipment

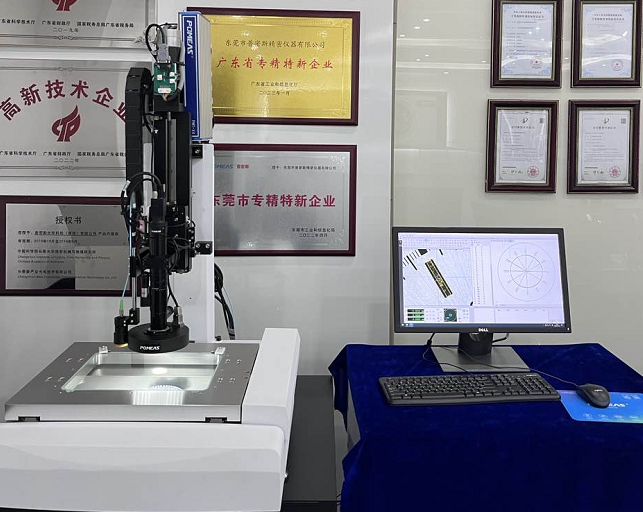

1. Image Measuring Instrument Series

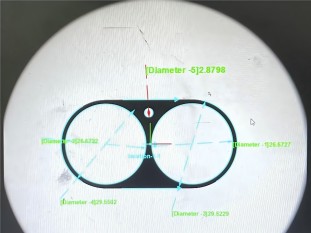

(1) 2D Image Measuring Instruments utilize high-resolution industrial cameras combined with telecentric optical systems to perform non-contact 2D dimensional measurements through image processing algorithms. They are commonly used for inspecting parameters such as length, width, height, angles, and arcs on flat components like PCB boards, rubber seals, and smartphone glass covers. Featuring micron-level repeatability (within ±2μm), they support automatic edge extraction and are suitable for thin-walled/soft workpieces.

(2) 3D Image Measuring Instruments build upon 2D technology by adding Z-axis motorized control and multi-angle rotary stages to perform 3D contour and spatial dimension measurements. Capable of adaptive light source adjustment, continuous zoom, and contact/non-contact probe coordination.

2. Fully Automatic Image Dimension Measuring Instruments (Flash Measurement Instruments)

Breaking through the limitations of traditional point-by-point sampling, this equipment employs area-scan data acquisition technology. It achieves full-dimension measurement of complex workpieces in seconds (e.g., 50 dimensions ≤ 3 seconds), enabling online full inspection of high-volume small precision parts (electronic connectors, watch gears). It integrates dual telecentric optical path design with deep learning defect recognition.

3. Composite Coordinate Measuring Machine (CMM)

In addition to the classic bridge design, configurations include gantry-type, articulated-arm, and in-line systems. Equipped with ceramic beams and air-bearing guides, they achieve absolute accuracy at the micrometer level. Optional components include touch-trigger/scanning probes, laser displacement sensors, and infrared temperature compensation units. These systems are suitable for dimensional and geometric tolerance inspection of large critical components such as automotive engine blocks and aerospace aluminum alloy frames.

II. Key Considerations for Model Selection Decisions

① Precision Requirement Grading: Standard machined parts require micron-level equipment, while precision molds demand sub-micron solutions.

② Production Efficiency Balancing: For daily inspection volumes exceeding 500pcs, prioritize flash inspection systems paired with robotic loading/unloading solutions.

③ Special Environment Adaptation: High-temperature/dust environments necessitate dedicated models with IP67 or higher protection ratings.

④ Data Interoperability: Modern measurement equipment must support SPC statistical process control interfaces and MES system integration capabilities.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com