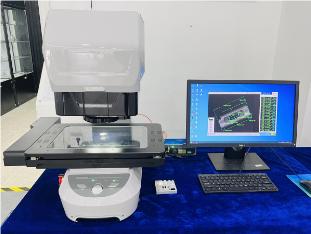

In today's era of deep integration between smart manufacturing and precision machining, enterprises face unprecedentedly stringent demands for component quality control. Particularly in fields such as plastic parts, precision molds, and electronic components, even minute dimensional deviations or surface defects can lead to degraded product performance or outright scrap. Conventional measurement tools struggle to meet the requirements for efficient, precise, and non-destructive inspection in the face of this challenge. The POMEAS MAX2 High-Precision Image Measuring System emerges as the solution, featuring a revolutionary technical architecture and outstanding performance. It has become the preferred choice for numerous enterprises seeking to upgrade their quality systems.

I. Breaking Traditional Constraints: Non-contact Measurement Balances Efficiency and Safety

Traditional contact measurement methods (such as coordinate measuring probes) can capture localized data, but they tend to cause indentation deformation on soft materials like silicone and TPU. Additionally, complex curved surfaces require multiple setups and adjustments, making the process time-consuming and labor-intensive. In contrast, the MAX2 employs a high-resolution optical imaging system. By integrating a high-speed camera with structured light technology, it achieves micron-level precision in non-contact measurement.

Advantages:

(1) Non-contact inspection: Enables measurement of sensitive components such as thin-walled parts and elastomers without physical contact;

(2) Full-dimension coverage: Simultaneously captures dozens of critical parameters including flatness, profile, height difference, and hole diameter in a single scan;

(3) Dynamic tracking capability: Supports real-time monitoring of injection molding processes, providing immediate feedback on shrinkage rate trends.

II. 3D Reconstruction Capabilities: Exposing Hidden Defects

Common plastic part defects such as warping and sink marks are easily overlooked under two-dimensional projection. MAX2 constructs 3D point cloud models based on binocular vision principles, enabling intuitive visualization of workpiece surface topography and spatial characteristics.

Technical Features:

(1) Ultra-high-definition detail capture: Equipped with telecentric lenses and ring-shaped LED cold light sources, it clearly identifies minute cracks as small as 0.01mm;

(2) Intelligent deviation analysis: Automatically compares against CAD design models, generating color difference contour maps and cross-sectional profile lines to precisely locate out-of-tolerance areas;

(3) Complex Surface Adaptation: Offers multi-angle stitching measurement solutions for freeform surfaces (e.g., curved phone backs) and irregular holes/slots.

III. Intelligent Operation: Lowering Professional Barriers and Unlocking Human Potential

Traditional measurement relies on experienced technicians manually focusing and selecting points, resulting in a high proportion of human error. MAX2 features a built-in AI algorithm engine that simplifies complex operations into a “one-click start.”

High measurement efficiency:

(1) Auto-Focus and Path Planning: Intelligently generates optimal scanning trajectories based on workpiece geometry;

(2) Graphical Programming Interface: Drag-and-drop command arrangement enables rapid adoption even for employees with no prior experience;

(3) Cloud-Based Data Management: Automatically archives measurement results, supporting cross-departmental collaborative analysis and traceability.

IV. Flexible Configuration: Adapting to Diverse Production Needs

Different industries have significantly varying requirements for measurement ranges and accuracy grades. MAX2 offers modular hardware configurations and software customization services to flexibly address diverse scenarios.

Customization Options:

• Field of View Expansion: Optional wide-angle lenses or motorized zoom objectives cover the full size range from micro connectors to large appliance housings;

• Function Overlay: Integrated laser thickness measurement modules and spectral confocal probes extend capabilities to multi-layer composite material analysis;

• Production Line Integration: Supports PLC communication protocols for seamless embedding into automated production lines, enabling unattended full inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com