Point Spectral Confocal vs. Laser Triangulation: Which is Suitable for Transparent Object Detection?

In the field of precision measurement, detecting the surface topography of highly reflective, transparent, and liquid objects has always been a technical challenge. Traditional laser triangulation methods, constrained by their underlying principles, often suffer from signal loss and data distortion when encountering mirror-like reflections, transparent media, or surfaces with large tilt angles. In contrast, point-spectral confocal sensors, leveraging their unique confocal optical structure and spectral analysis technology, have emerged as the ultimate solution for overcoming these challenges.

I. Technical Principle Comparison: Confocal Structure vs Triangulation

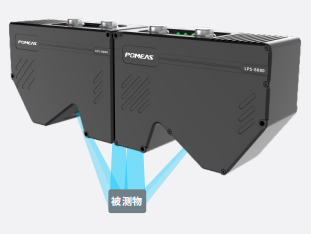

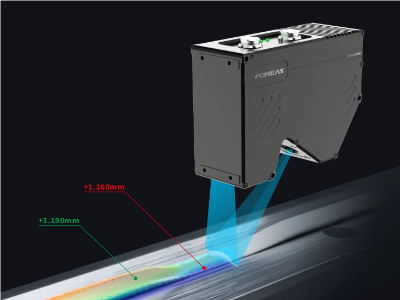

Laser triangulation is based on geometric optics principles. A laser beam illuminates the surface of the measured object, and the reflected light is imaged by a lens onto a position sensor (such as CMOS/CCD). Distance is calculated using the trigonometric relationship. Its core functionality relies on the fixed geometric relationship between the angle of incidence and the angle of reflection. When the surface tilt angle exceeds the threshold (typically within ±45°) or the material is mirror-like/transparent, the reflected light may fail to reach the receiver, creating measurement blind spots. For instance, when measuring the curved edges of a smartphone's glass cover, laser triangulation often fails due to excessive angles of incidence.

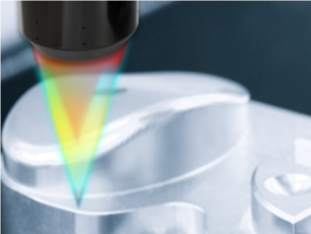

Point-spectrum confocal sensors employ a confocal optical design: a broad-spectrum polychromatic light beam is dispersed by a dispersive lens into monochromatic light, forming a sequence of focal points corresponding to continuous wavelengths within the measurement range. When the measurement light strikes an object's surface, only the wavelength matching the surface height is focused and reflected back to the spectrometer. Height values are directly converted using the wavelength-distance calibration curve. This principle renders it insensitive to incident angles. Even with surface inclinations up to ±88° (diffuse surfaces) or ±62° (specular surfaces), it captures reflected light through a coaxial optical path, enabling measurement without blind spots.

II. Core Advantages: Penetration Through Transparent Media and Resistance to Environmental Interference

1. Transparent/Liquid Object Measurement: Overcoming the “Invisibility” Limitation of Laser Triangulation

Laser triangulation relies on reflected light intensity, yet transparent objects (e.g., glass, liquids) transmit laser beams directly, leaving the receiver without a signal. Even when partial reflection occurs, overlapping reflections from multi-layer interfaces (e.g., coated glass) cause signal confusion. For instance, when measuring the thickness of a glass substrate in an LCD panel, laser triangulation requires separate measurements of the top and bottom surfaces. However, poor optical path penetration makes it difficult to capture data from both interfaces simultaneously.

Spectral confocal sensors overcome this limitation through a “transmission-reflection” mechanism: measurement light penetrates the first surface layer and reflects off the second. By analyzing the wavelength difference between these two reflected signals, the spectrometer directly calculates interlayer thickness. For instance, the POMEAS SFS-8022 can measure optical lenses as thin as 0.1mm with ±0.1μm precision.

2. High-Reflectivity Surface Measurement: Eliminating “Signal Overload” from Specular Reflection

When measuring highly reflective metals (e.g., aluminum alloys, stainless steel), specular reflection in laser triangulation causes receiver saturation, leading to “spot overflow” and inaccurate height readings. For instance, measuring the inner wall of an engine cylinder block's crankshaft bore often yields unstable data due to excessive reflected light.

Spectral confocal sensors employ a confocal optical path design that exclusively receives monochromatic light matching the focal point. Even on surfaces with reflectivity as high as 99% (e.g., chrome-plated surfaces), the spectrometer's narrow-band filtering capability eliminates stray light, ensuring signal stability.

3. Environmental Interference Resistance: Stable Output and Temperature Drift Control

Laser triangulation is sensitive to ambient light, where intense illumination (e.g., sunlight) interferes with receiver signals. Simultaneously, fluctuations in laser source power or temperature variations (e.g., high-temperature industrial environments) cause measurement drift. For instance, when measuring solar panel surface topography outdoors, laser triangulation requires additional light shielding and frequent recalibration.

Spectral confocal sensors employ a sealed optical path design where the spectrometer analyzes only specific wavelengths, automatically filtering out ambient light (e.g., visible light outside the 550nm band). Their optical lenses contain no electronic components, achieving a thermal drift coefficient below 0.01μm/℃ for long-term stable operation.

III. Typical Application Scenarios: From Consumer Electronics to Precision Manufacturing

1. Consumer Electronics: Measuring the curvature radius of smartphone glass covers, step height in camera modules (e.g., gaps between lenses and brackets), and OCA adhesive layer thickness on displays. Spectral confocal sensors simultaneously output 3D point cloud data, enabling “one-scan, full-dimensional inspection,” whereas laser triangulation requires multiple angle adjustments to cover curved surfaces.

2. Semiconductor Manufacturing: Measures wafer surface roughness (Ra < 0.5nm), chip encapsulation thickness (typically 50-200μm), and solder ball lead height. Spectral confocal sensors' nanometer-level resolution (e.g., HPS-CFL1000 by Haibosen reaching 0.1nm) meets advanced process requirements, whereas laser triangulation is inapplicable due to resolution limitations (typically ≥1μm).

3. Automotive Manufacturing: Inspecting the cylindricity of engine block crankshaft bore inner walls, the flatness of battery pack housings (e.g., weld seam smoothness on aluminum casings), and the curvature radius of headlight lenses. Spectral confocal sensors penetrate transparent lens covers to directly measure internal reflector topography, whereas laser triangulation requires lens cover disassembly for inspection.

4. Medical Applications: Measuring medical film thickness (e.g., infusion bag films at 50-200μm), surface roughness of artificial joints (Ra<0.1μm), and curvature radius of endoscope lenses. Spectral confocal sensors' non-contact measurement avoids contaminating biological samples, whereas laser triangulation may scratch surfaces upon contact.

Laser triangulation retains its cost advantage for measurements on flat, diffuse surfaces (such as simple displacement detection), but its fundamental limitations prevent stable data output when encountering highly reflective, transparent, or complex curved surfaces. Spectral confocal sensors achieve “complete immunity” to incident angle, material properties, and ambient light through confocal optical structures, spectral analysis technology, and anti-interference design, making them the preferred solution in precision manufacturing, semiconductors, consumer electronics, and other fields.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com