Amid the wave of Industry 4.0 and “Made in China 2025,” enterprises have set higher demands for efficiency, precision, and intelligence in production processes. Traditional manual quality inspection and sorting methods, plagued by low efficiency, fatigue susceptibility, and inconsistent standards, can no longer meet the needs of modern manufacturing. Against this backdrop, an integrated system combining a Telecentric Measurement System with a SCARA robotic arm has emerged. Functioning like equipping production lines with “eagle eyes” and “dexterous hands,” it enables real-time, 100% inspection and automated sorting of product quality. This system is increasingly becoming a powerful intelligent tool across various industries.

I. System Core: The Powerful Integration of Two Major Technologies

The outstanding performance of this integrated system stems from the seamless collaboration of its two core components:

Telecentric Measurement System

1. High-Precision Visual Inspection: Utilizing high-resolution industrial cameras and specialized image processing software, the system captures clear product images in an instant.

2. Rapid dimensional measurement: Based on the captured images, it performs precise measurements of various dimensional parameters—such as length, diameter, angle, and positional accuracy—at millisecond speeds, achieving micrometer-level precision.

3. Complex defect identification: Beyond measuring dimensions, it detects cosmetic defects including scratches, stains, burrs, missing parts, and misassembly, offering capabilities far exceeding traditional inspection fixtures.

SCARA Robot Arm

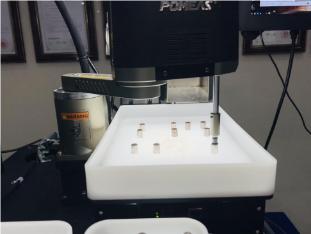

1. High-speed, high repeatability positioning accuracy: SCARA (Selective Compliant Assembly Robot Arm) robots deliver exceptional horizontal motion speed and repeatability, making them ideal for rapid pick-and-place operations.

2. Compact structure, space-saving: Its compact design facilitates seamless integration with other production line equipment, making it perfect for high-tempo sorting tasks in confined spaces. Stable and reliable: Industrial-grade reliability ensures continuous, stable operation 24/7.

3. Workflow: As products enter the inspection station, a Telecentric Measurement System instantly captures and analyzes images, instantly determining whether the product is “OK” (pass) or “NG” (fail). It then transmits the results and location data to the control system. The control system immediately instructs the SCARA manipulator to precisely pick up the product and place it into either the corresponding OK bin or NG bin. The entire process is seamless and fully automated.

II. Core Advantages: Why Has It Become the Industry's New Favorite?

Compared to traditional separate inspection and sorting stations, this integrated solution offers overwhelming advantages:

-

Ultimate Efficiency: Seamless integration of measurement and sorting operations significantly reduces cycle times and boosts production efficiency.

-

100% Full Inspection, Zero False Negatives: Eliminates the randomness and fatigue associated with manual sampling, ensuring consistent quality of outgoing products.

-

Data-Driven Traceability: All inspection data (dimensions, defect types, quantities, etc.) is recorded and reported, facilitating quality traceability and production process analysis while providing data support for process optimization.

-

Substantial Reduction in Labor Costs: Completely replaces monotonous quality inspection and sorting roles, freeing personnel for higher-value tasks.

-

High Flexibility: By swapping fixtures and adjusting software programs, the same system rapidly adapts to inspect and sort diverse products, making it ideal for flexible production models involving small batches and multiple varieties.

III. Wide-Ranging Applications: Empowering Intelligent Upgrades Across All Industries

The system's powerful versatility enables it to excel in numerous industries with stringent requirements for size and appearance:

- Electronics Industry: Dimension measurement and defect sorting for mobile phone components (e.g., mid-frames, camera modules), connectors, and chips.

- Automotive Components: Precision inspection and classification of small engine parts, seals, sensors, and other precision components.

- Precision Hardware: Dimensional compliance checks and good-part sorting for screws, bearings, precision springs, and similar products.

- Medical Devices: Inspection of products with stringent cleanliness and dimensional requirements, such as syringes, surgical blades, and dental implants.

- Plastics & Injection Molding: Detection of defects in injection-molded parts—including flash, short shots, and sink marks—followed by automated sorting.

- Food & Packaging: Verification of packaging integrity: label alignment, secure cap closure, and absence of foreign objects in products.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com