How Telecentric Measurement System Becomes High-Speed Production Line Measurement Equipment

I. The Dilemma of Synchronized Measurement on Production Lines

In large-scale manufacturing sectors such as automotive components, 3C electronics, and precision machinery, high-speed production lines have entered the “second-level era”—some assembly lines can complete the processing and transfer of a single product every 3-5 seconds. However, traditional quality inspection methods have long lagged behind: offline sampling inspections require halting production and moving samples, with each test taking several minutes or longer, making it impossible to cover the entire production run. Even manual online inspections struggle to keep pace with the high-frequency flow of the production line due to the limited speed of human judgment and susceptibility to fatigue. This contradiction of “fast production, slow inspection” leads to either superficial quality monitoring that risks batch defects or forced production line slowdowns to await inspection results. This directly lowers production efficiency, becoming a key bottleneck constraining capacity utilization.

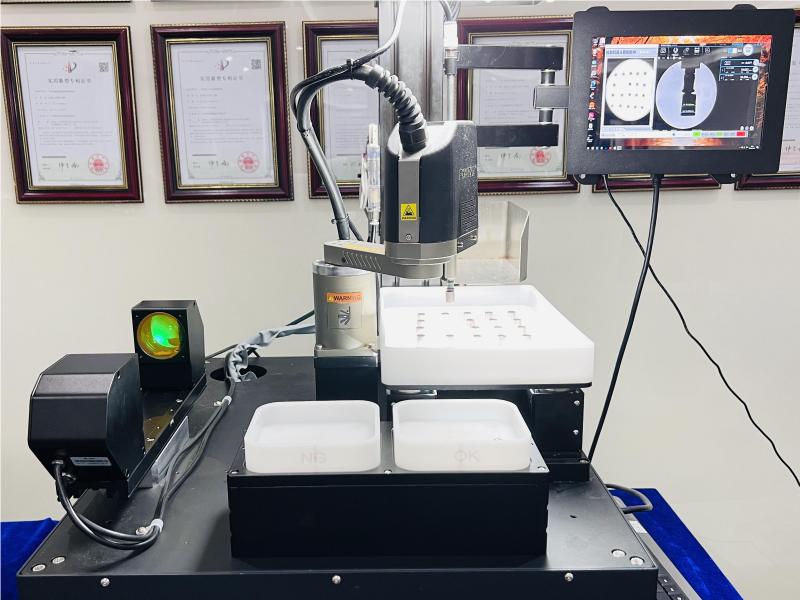

The “instant-result” online projector is precisely the solution to this core contradiction. Its core value lies in breaking down the barrier between inspection and production. With the dual advantages of “online deployment + high-speed response,” it integrates quality monitoring into the production cycle, becoming a ‘synchronizer’ for the production line rhythm rather than a “stumbling block.”

II. “Online” Feature: Seamlessly integrated into production lines, breaking through three barriers.

The “online” capability of the online projector represents a triple seamless integration of physical space, process flow, and data circulation—not merely a simple production line installation.

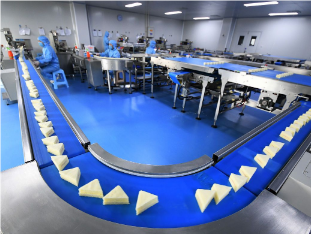

1. Physical Integration: Modular equipment design allows flexible embedding into critical workstations like stamping, injection molding, and assembly. It adapts to production line space constraints without requiring dedicated inspection zones. Some models support multi-station coordination, enabling millisecond-level automated loading/unloading via robotic arms and conveyor belts to eliminate manual intervention and handling delays.

2. Process integration achieves a closed-loop automation cycle of “production-inspection-feedback” through deep linkage with PLC systems: inspections automatically trigger when products reach inspection stations. Passed items proceed directly to subsequent processes, while defective items are automatically sorted. Defect data feeds back in real-time to control systems, enabling rapid process adjustments and making inspection a natural extension of production.

3. Data Flow: Inspection data is uploaded in real time to the MES system and correlated with production data (processing time, equipment parameters, etc.), forming a comprehensive quality traceability system. Managers can monitor inspection pass rates and defect distributions in real time, shifting quality monitoring from “post-event tracing” to “in-process alerts.”

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com