HDMI Industrial Cameras: A Comprehensive Analysis of Principles and Applications

I. Core Imaging Principle

The imaging process of HDMI industrial cameras is based on photoelectric conversion and digital signal transmission technology, with its core workflow divided into three stages:

1. Optical imaging stage: Light reflected from the object is focused through the lens and projected onto the surface of the image sensor (CCD or CMOS). The sensor surface is covered with millions of tiny photosensitive elements (pixels), each independently receiving light signals and converting them into electrical signals. For example, a certain model of HDMI industrial camera employs a 1/2.3-inch CMOS sensor with pixel dimensions of 1.335μm × 1.335μm and a total pixel count of 21 million, enabling high-resolution image capture.

2. Signal Processing Stage: The electrical signals output by the sensor are amplified by an amplifier before being converted into digital signals via an analog-to-digital converter (ADC). Some high-end models (such as HDR-enabled HDMI industrial cameras) perform multi-level dynamic range adjustments during this stage to preserve detail in both bright and dark areas within high-contrast scenes (e.g., welding inspection). For instance, one camera utilizes 100dB dynamic range technology to simultaneously display reflective areas and shadow details on metal surfaces.

3. Digital Output Stage: Processed digital image data is transmitted via the HDMI interface in pure digital format to displays or storage devices. The HDMI interface supports resolutions up to 4K (3840×2160) and frame rates of 60fps, ensuring uncompressed, latency-free image transmission. For instance, a specific HDMI industrial camera model can output 1920×1080 resolution images in real-time at 60fps, meeting high-speed inspection requirements.

II. Typical Application Scenarios

HDMI industrial cameras enable critical applications across multiple fields with their high resolution, low latency, and easy integration:

- Precision Manufacturing Inspection

- Case Study: In semiconductor packaging inspection, HDMI industrial cameras capture chip pin soldering defects using a 21-megapixel sensor, achieving detection accuracy of ±0.005mm.

- Advantages: High resolution (e.g., 5 megapixels or higher) clearly reveals micron-level defects. Combined with telecentric lenses, it eliminates perspective distortion, making it ideal for high-precision dimensional measurement.

- High-Speed Motion Capture

- Case Study: In the textile industry, HDMI industrial cameras monitor fabric surface defects in real time at 60fps, achieving inspection speeds of 100 meters per minute.

- Advantages: High frame rates (e.g., 100fps+) eliminate motion blur, while global shutter technology captures sharp images of fast-moving objects.

- Research-grade imaging analysis

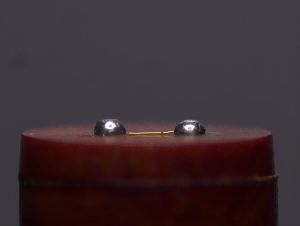

- Case Study: In materials science research, HDMI industrial cameras combined with polarizing filters analyze the polarization characteristics of metal fatigue cracks, providing data support for material life prediction.

- Advantages: Supports multispectral imaging (e.g., visible light, near-infrared), and can be extended to specialized applications such as fluorescence detection and 3D contour measurement.

- Medical and Bioimaging

- Case Study: In cell culture monitoring, an HDMI industrial camera equipped with a macro lens (e.g., 5X-10X magnification) observes the cell division process, achieving an image resolution of 0.1μm/pixel.

- Advantages: Low distortion design (distortion rate <0.05%) ensures image geometric accuracy, making it suitable for medical image analysis.

III. Key Parameters for Model Selection

When selecting an HDMI industrial camera, matching should be based on the following core parameters:

- Resolution and Pixel Dimensions

- Rule: Resolution must meet inspection accuracy requirements (Formula: Resolution ≥ Object dimension / Inspection accuracy × Safety factor). For example, when inspecting a 10mm object with an accuracy requirement of 0.01mm, a camera with a resolution ≥ 1000 × 1000 must be selected.

- Frame rate and exposure time

- Rule: Frame rate must exceed object movement speed (Formula: Frame rate ≥ Production line speed / Detection step size). For example, with a production line speed of 1m/s and a single-frame field of view of 10mm, a camera with a frame rate ≥ 100fps must be selected.

- Interfaces and Bandwidth

- Rule: HDMI interfaces must match data transmission requirements. For example, 4K resolution (3840×2160) images require an HDMI 2.0 interface supporting 60fps transmission, while 1080p resolution (1920×1080) only requires an HDMI 1.4 interface.

- Special Function Requirements

- HDR Mode: Ideal for high-contrast scenes (such as welding inspection), it preserves both bright and dark details through multi-level dynamic range adjustment.

- Polarization Imaging: Analyzes surface stress distribution on objects through polarizing filters, suitable for defect detection in materials such as glass and metal.

- Multispectral support: Combines near-infrared (NIR) or ultraviolet (UV) light sources to enable fluorescence detection or material composition analysis.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com