Continuous Zoom Microscope Optical System

1. Zoom objective group: ① Structure: adopts multiple lenses (front group, zoom group, compensation group, rear group) to work together to achieve continuous adjustment of magnification by moving the zoom group and compensation group to change the focal length of the system; ② Zoom range of 0.7 × ~ 4.5 × high zoom ratio requires complex optical compensation design. ③ Aberration Correction: Correct chromatic aberration and spherical aberration through aspherical lens, low dispersion material (such as fluorite) or composite lens group to ensure clear imaging within the full magnification range.

2. Parallel optical path design: Adopting infinite-aperture optical system (objective lens separated from the barrel lens) allows insertion of auxiliary modules (e.g., filters, polarizers) without affecting the imaging quality.

3. Industrial Camera Auxiliary: Combines CMOS/CCD high definition industrial camera and image processing algorithms.

Mechanical structure of continuous zoom microscope system

1. Zoom adjustment mechanism: ① High precision cam mechanism controls the synchronized movement of lens group to ensure the linearity and repeatability of zoom. ②Integrated encoder monitors the zoom position in real time, with software to realize magnification display and automatic calibration.

2. Stability and sealing: the mechanical structure should be dustproof and shockproof, and the aluminum alloy or magnesium alloy frame should be used to avoid thermal expansion and contraction affecting the alignment of the optical path.

Continuous zoom microscope illumination system

1. Coaxial/annular illumination: ① Coaxial light is suitable for highly reflective surfaces (e.g. metal), annular light is used for three-dimensional illumination of biological samples. ② Brightness Adaptive: automatically adjust the intensity of the light source when zoom to avoid overexposure at high magnification or insufficient brightness at low magnification.

2. Dark field/polarized light illumination: optional module supports dark field (observe transparent samples) or polarized light (analyze crystal structure) mode.

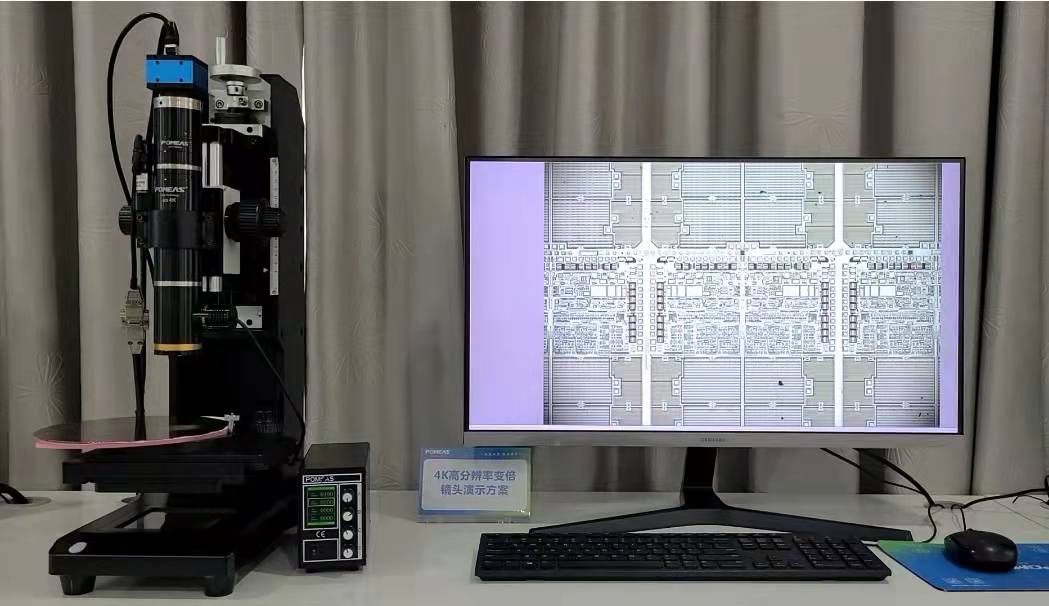

Case of continuous zoom microscope system

1. Industrial inspection: PCB circuit board welding quality inspection (5×~50× continuous zoom).

2. Life science: dynamic observation of living tissue (fluorescence imaging + zoom tracking).

3. Micro-nano manufacturing: semiconductor chip defect analysis (with long working distance objective lens).

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION