Differences between Image Measuring Instruments and Picture Measuring Instruments

Principle of Image Measuring Instrument

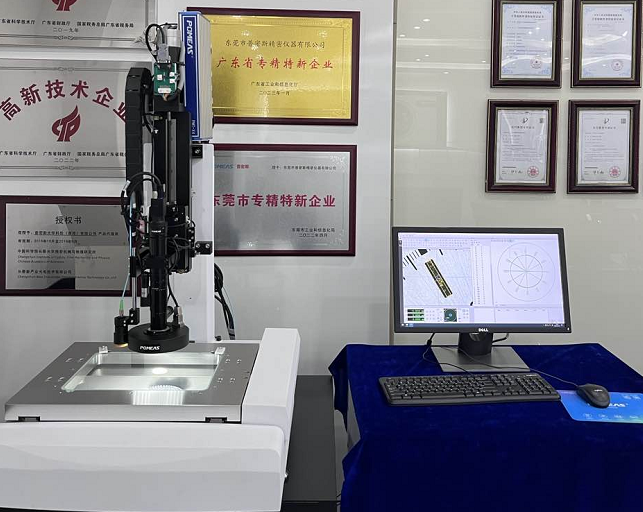

1. Optical Magnification: Optical magnification imaging of the object to be measured by means of a microscope or a high-magnification lens (e.g. 30-500x zoom).

2. Image Acquisition: Optical images are converted into electrical signals using a CCD/CMOS sensor and transmitted to a computer.

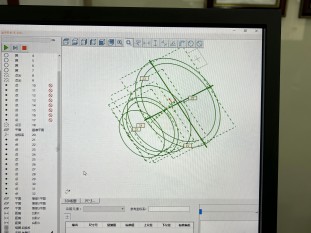

3. Digital Processing: De-noise, edge detection, feature extraction (e.g., circle, line, angle) and other processing of the image through specialized software.

4. Geometric Calculation: Based on the principle of spatial geometry, combined with the grating scale displacement data, calculate the object size, shape and position.

5. Autofocus: drive the lens or sensor by Z-axis motor, combined with machine vision algorithm to realize micron-level accurate focusing.

6. Calibration and Compensation: Utilizing standard parts to calibrate optical aberration, temperature error, etc. to ensure measurement accuracy.

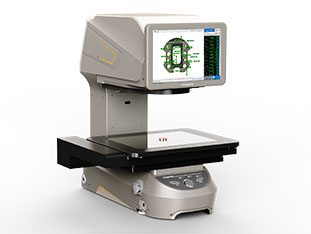

Principle of Image Measuring Instrument (Flash Meter)

1. Telecentric imaging: adopts 2000w pixels dual telecentric lenses to eliminate parallax and ensure distortion-free image under large field of view.

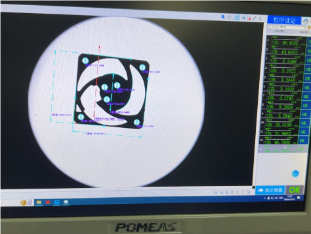

2. Intelligent Algorithm: Rely on image matching and 3D reconstruction algorithm, support multi-size simultaneous measurement and one-key flash measurement.

3. Fast processing: accelerate image processing by FPGA or GPU to realize real-time online measurement.

4. Automation: Support multi-product and multi-feature parallel measurement, and automatically generate parameter evaluation report.

Image Measuring Instrument Technology Advantage:

① Large Stroke Measurement: Supports global inspection of large-size workpieces (e.g. molds, automotive parts).

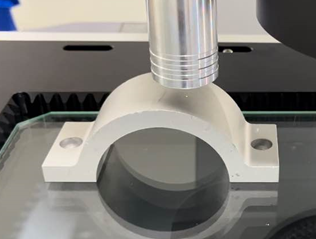

② Composite function: contact probe can be integrated to realize complementary measurement of 2D image and 3D coordinates.

Image Measuring Instrument (Flash Meter) Technical Advantages:

① Telecentric optical path: avoid edge distortion of traditional lenses, suitable for high-precision industrial inspection.

② Online real-time: support production line integration to achieve 100% full inspection, such as PCB solder joints, cell phone glass size monitoring.

Selection Recommendations

If you need to measure large workpieces, complex three-dimensional contours, or very high requirements for measurement accuracy (such as mold development, reverse engineering of precision parts), then choose the image measuring instrument; if you need to quickly batch testing of small precision parts (such as screws, gears, electronic components), or for the convenience and efficiency of the operation of a higher demand for the choice of image measuring instrument.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com