Laser profile scanning technology has become the core driving force of industrial automation in the current demand for intelligent manufacturing and precision inspection. As an industry leader, POMEAS has launched LPS line laser profile sensors, which are widely used in various industries due to its breakthrough technology architecture and multi-scenario adaptability.

LPS Series Laser Sensor Introduction

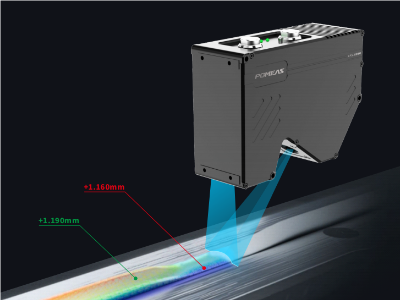

POMEAS LPS sensors are based on the laser triangular reflective principle, whereby a precision optical system expands the laser beam into a static laser line, which is projected onto the surface of the object to be measured.

Advantages of LPS Series Laser Sensors

1. Sub-micron accuracy: Repeat measurement accuracy up to 0.5μm, can accurately capture the micron-level deformation of the surface of the metal parts, and can even detect the metal chip particles of 0.1mm³;

2. Ultra high-speed sampling: the highest support for 10kHz scanning frequency, in the automotive tire dynamic inspection scene, can achieve more than 10,000 times per second real-time data acquisition;

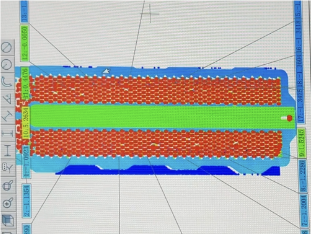

3. MetX intelligent algorithm: built-in high-precision algorithms and multi-frame fusion technology, in the battery compartment detection, through the point cloud feature analysis can automatically distinguish between static adhesion and dynamic foreign objects, risk assessment accuracy increased by 40%.

LPS Series Laser Sensor Measurement Solutions

① Basic parameter measurement: 12 2D profile parameters such as height, width, angle and radius can be acquired synchronously. In semiconductor package inspection, the measurement error of IC pin spacing is controlled within ±1μm;

② Three-dimensional shape analysis: combined with the longitudinal displacement data, the three-dimensional shape of the object surface can be reconstructed, in the cell phone curved screen inspection, the curvature radius measurement accuracy of 0.01mm;

③ Defect identification: using adaptive exposure algorithm and polarization filtering technology, effectively suppressing metal reflection interference, in the new energy vehicle battery compartment detection, the impurity identification rate exceeds 99.99%;

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION