Precision Measurement Lenses: Large Depth-of-Field Telecentric Lenses vs Standard FA Lenses

I. Core Requirements for Precision Measurement: High Accuracy, Interference Resistance, Full Coverage

The objective of precision measurement is to obtain accurate dimensions, contours, and positional relationships of objects (such as hole diameters, height differences, and spacing), for example:

① Full Coverage Imaging: Any surface irregularities or height differences (e.g., steps on mechanical parts, components on circuit boards) must be clearly imaged across all measurement areas simultaneously;

② Sharp Edge Definition: Object edges (e.g., corners, hole perimeters) must be clearly distinguishable to prevent measurement errors caused by noise or blurring;

③ Positioning Tolerance: Measurement results remain unaffected by slight tilting of the object or minor deviations in its position relative to the lens (i.e., minimal “perspective error”).

II. Deep-Focus Telephoto Lenses: Precisely Matching Precision Measurement Requirements

1. Large Depth of Field: Solving the Imaging Challenge of “Uneven Surfaces”

Depth of field refers to the range of object distances a lens can render sharply. A large depth of field means that even when an object's surface has unevenness (such as a part with a 5mm height difference), all areas—both high protrusions and low depressions—can be captured clearly simultaneously.

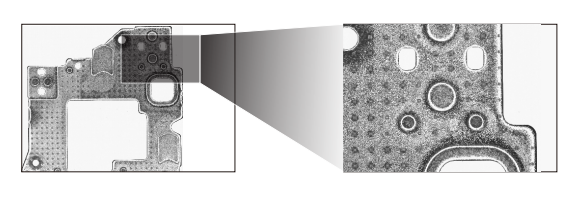

When measuring a metal part with a groove, where the groove bottom is 3mm below the part surface, a large depth-of-field telecentric lens can clearly capture both surface and groove bottom details simultaneously, ensuring accurate measurement of both dimensions. In contrast, a standard FA lens (fixed focal length, shallow depth-of-field) may only clearly capture the surface, while the groove bottom falls outside the depth-of-field range and appears blurred, rendering measurement impossible.

2. Telecentric Properties: Eliminate “Perspective Distortion” and Enhance Measurement Stability

The core of a telecentric lens lies in its “object-side telecentric” design—where the lens's principal rays are parallel to the optical axis (i.e., perpendicular to the imaging plane). This characteristic eliminates “perspective distortion.”

① Conventional lenses exhibit “perspective distortion”: When an object slightly deviates from the lens's optimal working distance (e.g., moving 1-2mm forward/backward) or tilts slightly, the size/shape of the image undergoes minor changes (similar to how the human eye perceives distant objects as smaller and nearby objects as larger). For example, when measuring a 10mm part, if the object moves 1mm closer to the lens, a standard lens might capture an image of “10.2mm,” causing measurement errors.

② Telecentric lenses eliminate this issue: regardless of minor object movement or tilt within the depth of field, the size and shape of the image remain virtually unchanged, ensuring stable measurement values. This is critical for precision measurement (often requiring error ≤0.01mm).

3. Strong Edge Detection: Filtering Noise, Locking True Boundaries

In precision measurement, an object's “edge” serves as the reference point for dimensional calculations (e.g., hole diameter must be measured from edge to edge). Deep-depth-of-field telecentric lenses utilize optical designs (such as specialized lens groups and light-blocking structures) to minimize interference from lens flare and reflective noise on edges. They enhance contrast between edges and background, sharpening boundaries (e.g., metal part edges, glass edges).

III. Limitations of Ordinary FA Lenses: Suitable for Inspection, Difficult to Achieve Precision

Standard FA lenses (primarily fixed-focus) offer advantages such as high resolution and low distortion (suitable for visual positioning and defect detection), but they have significant limitations in precision measurement:

① Shallow depth of field: Fixed-focus design limits the range of clear imaging distances. If an object's surface is uneven, only partial areas remain sharp while others appear blurred (e.g., when measuring plastic parts with protrusions, the raised areas are clear while recessed areas are blurred, preventing complete data acquisition);

② Significant perspective distortion: Minor shifts in object position (e.g., slight displacement due to conveyor belt vibration) cause fluctuations in image size/shape. Precision measurement has extremely low tolerance for such variations (errors may amplify by over 10 times);

③ Weak edge interference resistance: Conventional lenses struggle with complex surfaces (e.g., reflective metals, transparent glass), being susceptible to stray light and reflections that cause blurred boundaries.

The core of precision measurement lies in “acquiring stable, unbiased dimensional data on complex surfaces.” The characteristics of a large-depth-of-field telecentric lens—combining “large depth of field (full coverage) + telecentricity (error resistance) + robust edge detection (precise boundaries)”—perfectly align with this requirement.

While standard FA lenses excel in visual inspection and positioning tasks, their limited depth of field and perspective errors prevent them from meeting the stringent requirements of precision measurement for “high accuracy and interference resistance.” Consequently, in the field of precision measurement, long-depth-of-field telecentric lenses have become the inevitable choice.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com