Application of Telephoto Lenses in Online Dimension Inspection of Precision Components

I. Requirements and Challenges for Online Dimension Inspection of Precision Components

The dimensional accuracy of precision components—such as automotive parts, electronic components, and medical device accessories—directly impacts product performance and assembly quality. Therefore, efficient and accurate in-line inspection is essential during production. Traditional inspection methods, including manual caliper measurement and offline sampling, suffer from low efficiency, high subjectivity, and susceptibility to missed defects, making them inadequate for modern mass production demands.

Vision inspection technology has emerged as the mainstream solution due to its non-contact, high-speed, and high-precision advantages. Lens performance directly determines inspection accuracy—telecentric lenses, with their unique optical characteristics, have become the core choice for precision dimensional measurement applications.

II. Core Advantages of Telephoto Lenses: Why Are They Suited for Precision Measurement?

Telecentric lenses (such as the LTDC0088/0176-120 mentioned in the case study) feature the following key characteristics through specialized optical design, making them perfectly suited for precision component dimensional inspection:

1. Low distortion rate: Minimal optical distortion (typically < 0.1%) prevents image distortion caused by the lens itself, ensuring accuracy of raw dimensional measurement data.

2. Constant magnification: Object image size remains largely unchanged during movement within a defined range, unaffected by minor object-to-lens distance variations (suitable for scenarios with slight part position fluctuations on assembly lines).

3. Adaptable depth of field: Maintains clear imaging for precision parts of varying thicknesses, enabling simultaneous measurement of multidimensional dimensions (e.g., height, thickness, aperture).

4. Strong anti-interference capability: Effectively filters environmental stray light while enhancing part edge features when paired with specific illumination sources (e.g., top light, bottom light).

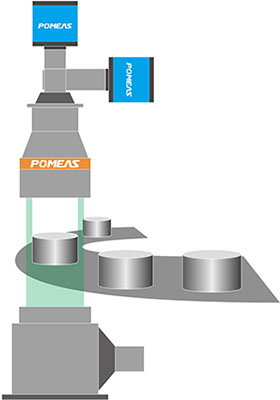

III. Practical Implementation Plan: Hardware-to-System Integration

① Hardware:

1. Telecentric Lens (LTDC0088/0176-120): Delivers distortion-free, high-contrast part images, establishing a foundation for subsequent measurements.

2. Monochrome Industrial Camera (CCN-200G25BSC): High resolution (e.g., 2 megapixels) ensures capture of minute dimensional details (e.g., tolerances at the 0.01mm level).

3. Multi-Light Source Synergy: Front lighting illuminates part surfaces, bottom lighting highlights contours, and gap lighting enhances edge contrast in minute gaps/holes—resolving imaging challenges for complex structural components.

② Software:

The AI intelligent measurement system combines high-quality images captured by telecentric lenses with AI algorithms to enable batch online inspection at production line speeds (e.g., tens to hundreds of parts per second). It automatically identifies dimensional deviations (such as length, diameter, angle, etc.), generates inspection reports, and triggers sorting actions (separating qualified/unqualified parts). It records dimensional data for each batch of parts, aiding in production process optimization.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com