Can a zoom lens with dual heads truly capture both the big picture and the fine details?

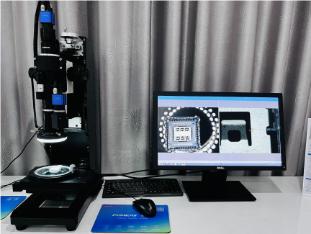

In the realms of industrial manufacturing and intelligent inspection, precision and efficiency remain eternal pursuits. From screening minute defects in precision electronic components to comprehensive quality control of large mechanical parts, every step relies on the robust support of advanced inspection technologies. The POMEAS Variable Zoom Lens, with its unique dual-head design, stands out in Eagle Eye visual inspection solutions, serving as a capable assistant for numerous industries to elevate inspection standards and achieve intelligent upgrades.

One Lens, Two Perspectives: A Revolutionary Approach to Simultaneously Capturing Global and Detailed Information

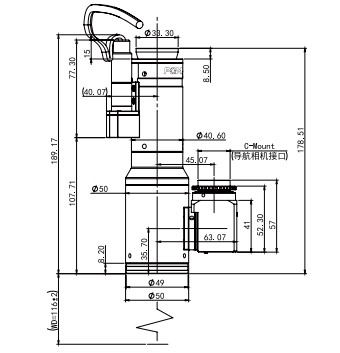

Traditional inspection lenses often face a dilemma: either they prioritize wide-area overviews but struggle to capture fine details, or they zoom in on specifics while losing sight of the entire scene. The POMEAS zoom lens breaks this limitation through an innovative dual-head design. A single lens cleverly integrates two high-definition imaging units, effectively granting the inspection system dual identities: a “global observer” and a “detail magnifier.”

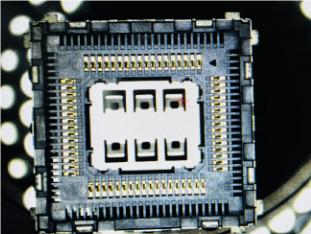

One imaging unit handles global observation, providing a wide field of view that covers the entire inspection area. It rapidly captures the product's overall contour, positional information, and macro-level surface features. Whether performing appearance integrity checks on large workpieces or evaluating the layout rationality of complex assemblies, it completes comprehensive scanning in an instant. This provides precise positioning and reference points for subsequent detailed inspections.

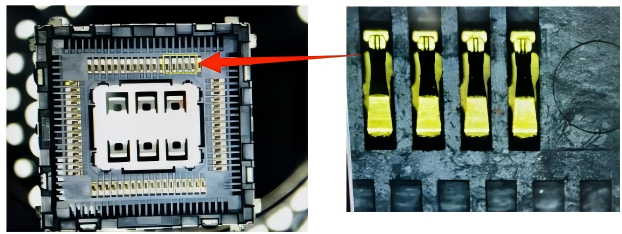

Another imaging unit specializes in detail magnification. With its high resolution and exceptional imaging quality, it enables meticulous observation and analysis of minute surface defects, subtle textures, and critical dimensions on products. Even the tiniest scratches, cracks, or impurities cannot escape its keen scrutiny, ensuring every potential quality issue is promptly identified and addressed.

This capability to simultaneously display both the big picture and fine details makes the inspection process more efficient and accurate. Operators no longer need to frequently switch between different lenses or inspection modes, significantly reducing inspection time and boosting production efficiency. At the same time, comprehensive inspection data provides more reliable basis for quality control and process improvement, helping enterprises continuously enhance product quality and market competitiveness.

Eagle Eye Visual Inspection Solution: The Powerful Backbone of Precision Detection

The seamless integration of POMEAS zoom lens navigation lenses with the Eagle Eye vision inspection solution establishes a comprehensive, high-precision intelligent inspection system. Leveraging advanced image processing algorithms and machine learning technology, the Eagle Eye solution performs real-time analysis and processing of captured images, automatically identifying and classifying various defect types while delivering accurate inspection results and evaluation reports.

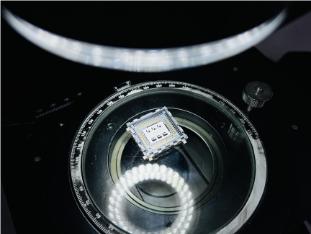

In the electronics manufacturing industry, quality inspection of minute components like chips and circuit boards is critical. The high resolution and detail capture capability of the POMEAS Zoom Lens clearly reveals key information such as solder joint quality, pin spacing, and component packaging on the surface of these components. The Eagle Eye Vision Inspection Solution intelligently analyzes these images to rapidly and accurately detect common defects like cold solder joints, short circuits, and open circuits, ensuring every circuit board meets high-quality standards.

In automotive manufacturing, appearance inspection and dimensional measurement of body components are vital for ensuring vehicle safety and aesthetics. POMEAS zoom lens enable rapid scanning of entire component surfaces to detect cosmetic defects like scratches, dents, or deformation. Their detail magnification capability allows precise measurement of critical dimensions—such as hole diameters and thread depths—ensuring manufacturing accuracy aligns with design specifications. The Eagle Eye vision inspection solution integrates and analyzes this data, providing robust support for quality control throughout production.

Wide-ranging Applications: Empowering Intelligent Upgrades Across Multiple Industries

POMEAS zoom navigation lenses have gained widespread adoption across numerous industries due to their exceptional performance and flexible applicability. Beyond electronics manufacturing and automotive production, they play a vital role in high-precision sectors such as biology, electronics, semiconductors, and machine vision.

In aerospace, components demand the highest standards of quality and reliability. POMEAS zoom lens enables high-precision inspection of critical parts like aircraft engine blades and airframe structural components, ensuring surfaces are free from defects such as cracks and porosity to safeguard flight safety.

2. In the medical device industry, product quality and safety directly impact patient health and lives. POMEAS zoom navigation lenses rigorously inspect surface finish, dimensional accuracy, and internal structures of medical devices, ensuring each product meets stringent medical standards.

3. In the semiconductor industry, defect detection during chip manufacturing is critical for ensuring chip performance and yield rates. POMEAS zoom navigation lenses meet the industry's demanding requirements for inspection speed and precision through their high resolution and rapid imaging capabilities, providing robust assurance for enhancing chip quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com