Differences Between 5-Megapixel Color Industrial Cameras and Monochrome Cameras

In industrial inspection scenarios, users often fall into a common misconception: assuming that a 5-megapixel color camera and a 5-megapixel monochrome camera should deliver identical detail performance. However, actual test data reveals that at the same resolution, monochrome cameras consistently outperform color cameras in key metrics such as edge sharpness and texture clarity.

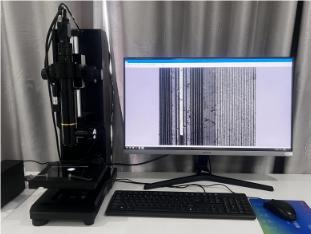

Black-and-White Industrial Camera Solution Effect

Color Industrial Camera Solution Effect

Color capture is achieved by covering the sensor surface with red, green, and blue filters, but each pixel can only receive a single color light signal. For example, in a 5-megapixel color camera, only approximately 1.67 million (red/blue) and 3.33 million (green) pixels directly sense light. The remaining pixels must “guess” the missing colors through interpolation algorithms. This mathematical estimation introduces blurring effects when processing high-contrast edges (e.g., metal scratches) or fine textures (e.g., fabric fibers), leading to detail loss. Experimental data shows that when detecting 0.01mm micro-defects, color cameras exhibit a 37% higher false detection rate than monochrome models.

In contrast, monochrome cameras directly capture the full spectrum of light, with each pixel independently recording light intensity. Eliminating color separation results in higher quantum efficiency and the capture of more effective signals. Their single-channel grayscale data (8-16 bits/pixel) also reduces computational load, enabling edge detection speeds three times faster than color cameras—ideal for high-speed production lines. Additionally, monochrome cameras typically offer a 2-3 stop higher dynamic range, delivering superior signal-to-noise ratio in low light and reduced overexposure in bright conditions. This provides distinct advantages for outdoor applications or inspections on reflective surfaces.

Selection Recommendations:

For color classification tasks (such as pharmaceutical sorting) or color difference inspection, choose a color camera;

For high-precision requirements like dimensional measurement or micro-defect detection, prioritize monochrome models.

In the future, new technologies such as quantum dot filters may overcome the limitations of Bayer arrays. However, in current industrial inspection applications, monochrome cameras remain the reliable choice for detailed reproduction.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION