How Laser Profile Sensor Solve Your Various Measurement Requirements

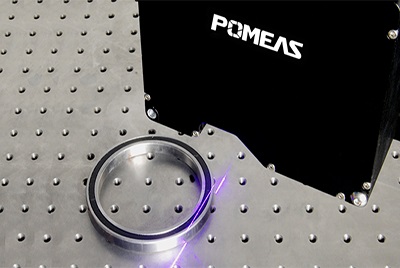

The laser profilometer developed by POMEAS scans the three-dimensional profiles of different surfaces using the principle of laser triangulation. Laser beams are amplified by a set of special lenses to form a static laser line and projected onto the surface of the object under test. The high quality optical system projects the diffuse reflected light of the laser line onto the sensitive sensor matrix.

In addition to the distance information (Z axis) from the sensor to the object under test, the controller can also calculate the position along the laser line (x axis) through this set of images. The sensor eventually outputs a set of two-dimensional coordinate values. The origin of the coordinate system is relatively fixed with the sensor itself. By moving the measured object or sensor, the three-dimensional measurement results can be obtained. Laser Profile Sensor Solves Your Various Measurement Requirements.

1. Non-contact measurement

Laser profilometer is a typical non-contact measuring sensor, which uses the profiles generated by laser beam on the surface of the target to measure the three-dimensional profiles. It has the characteristics of no measuring force, no wear and long life, and can work in various workplaces for a long time.

2. High measurement accuracy

At present, the repetition accuracy of POMEAS laser profile sensor can reach 0.2um.

3. Fast measurement speed

At present, the maximum sampling frequency of laser profile sensor can reach tens of kHz.

4. Multiple Measurement Parameters

Laser profile sensor can measure many two-dimensional profile parameters, including height, height difference, position, centroid position, width, center distance, point-point distance, point-line distance, radius, angle, inclination, centroid position, cross-sectional area, standard profile deviation, etc. When combined with longitudinal displacement information, three-dimensional shape can be obtained. Information, powerful.

5. Wide scope of application

Because the laser profile sensor uses laser as the measuring medium to realize the accurate measurement of the two-dimensional profile parameters of the target, it has no too many restrictions on the target to be measured, including hard and soft, hot and cold, black and white, light and shade, etc. It is especially suitable for some soft targets (such as rubber, plastic, film, etc.) and narrow space (such as parts). Grooves, blind holes, IC pins, etc.

Application of measurement function

On-line measurement of spacing, contour, steps, angles...

Defect detection, flatness detection

Contour Tracking, Dimension Measurement, 3D Scanning

Contour transmission or measurement data output

Strong and durable, suitable for production line and laboratory use

Suitable for Robot Applications

Multiple Scanning Applications

For integrators and end users, more applications await your development...

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com