Introduction

In the whole machine vision system, machine vision lens is the image acquisition part of the important imaging components. Because of the constraints of the entire system, so the machine vision lens selection is correct or not directly affect the entire machine vision system. The following POMEAS optical vision system vendors with years of customer real case, from the following aspects to analyze the machine vision lens selection points:

First, the special requirements of customers

Generally preferred to consider the special requirements of the machine vision lens, such as: in the machine vision lens and the workpiece before adding other devices (lenses, reflective lenses, glass), machine vision lens working environment.

Mainly have the following points need to confirm:

1. the installation space is limited requirements: machine vision lens size, length and other parameters;

2. fixed camera hanging lens: for example, some cameras can not be hung heavy machine vision lens;

3. the camera system needs movement: too fast, because of inertia, camera system may be offset;

4. the spectral response of special requirements: for example, for the UV environment, ordinary glass lens will absorb almost all of the UV light;

5. the need for machine vision lens plus light source: According to the scene environment, for the need to increase the brightness, will have to add light. If it is a coaxial lens, you can install point light;

6. the price requirements;

7. machine vision lens working environment;

8. whether there are other special components;

Second, the need for telecentric lens

For precision measurement systems need to use telecentric lens. Telecentric lens is the most important function is to overcome the perspective difference (imaging distance due to the different magnification caused by the phenomenon of inconsistencies), making the detection target in a certain range of motion when the size of the data is almost unchanged. In general, telecentric lenses are fixed focal length and working distance, and some telecentric lens is very large, some weight will be more than ten pounds, the need for detailed understanding of the size of the field of view, working distance, space constraints, and Motion control requirements, and then to determine the required lens model specifications. General surface defects detection, with or without judgments on the object imaging is not strictly required, the selection of distorted small telecentric lens.

Third, the machine vision lens depth of field

Some special requirements of the visual system requires a relatively large depth of field lens. For example, some of the detection or measurement must be the angle of the industrial camera and require the entire object image clarity; the measured object is not in the same plane, which need to consider the lens depth of field.

The smaller the focal length, the larger the depth of field. The smaller the aperture, the greater the depth of field. The farther the lens is from the object, the larger the depth of field. Small apertures and good light make focusing easier, but small apertures lose the fine structure of the object. The larger the camera chip, the larger the depth of field.

Fourth, the machine vision lens chip size

Each machine vision lens can only be compatible with the chip does not exceed a certain size of the camera. So the machine vision lens must first determine the industrial camera chip size, in order to ensure the quality of the entire image, machine vision lens maximum adapter chip size must be greater than the chip size associated with it, otherwise it will cause serious distortion and phase difference .

Fifth, the machine vision lens interface

The machine vision lens interface and the camera interface are divided into C, CS, F and other larger-sized interface types. Camera and lens are complementary, that is, C interface camera can only use C interface lens.

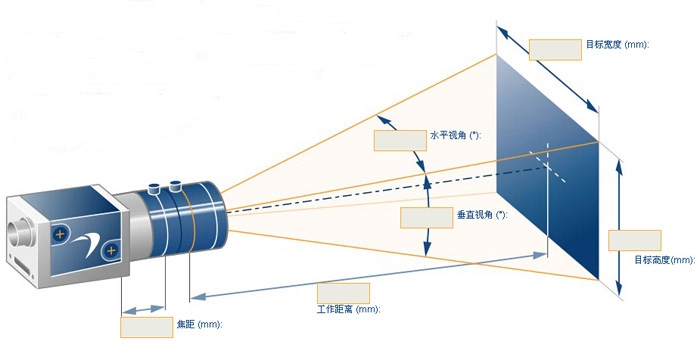

Sixth, the machine vision lens focal length

The focal length of the lens of the main field of view, working distance have a greater impact. In determining the focal length of machine vision lens must first determine the field of view, working distance, camera chip size and other factors.

Senventh, machine vision lens distortion

Distortion is the distortions caused by the local magnification in the field of view. Due to the impact of the production process, the lens distortion is inevitable, the better the distortion of the lens smaller. Generally in the precision measurement system and other high precision requirements, we must consider the machine vision lens distortion.

Please refer to POMEAS Selection Tool of the machine vision lens. Also visit POMEAS Vision Optics Produts for more excellent machine vision optical product information.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com