Industrial lens aperture f / # how to affect the depth of field it? For this question, we have to start from the industrial lens aperture and the depth of the basic concept of talking about. Aperture (Aperture) is the industrial camera lens by a few pieces of very thin metal sheet, the middle through the light. By changing the size of the hole to control the amount of light into the industrial lens. The greater the aperture, the more the amount of light entering the lens through the industry. The aperture value is usually expressed in f / #.

While the depth of field refers to the scene can be produced in a more clear image of the nearest point to the farthest point of the distance. The longer the depth of field, the greater the range of clarity. The following is a professional machine vision system supplier POMEAS shares professional lens knowledge under industry lens aperture f / # how to affect depth of field.

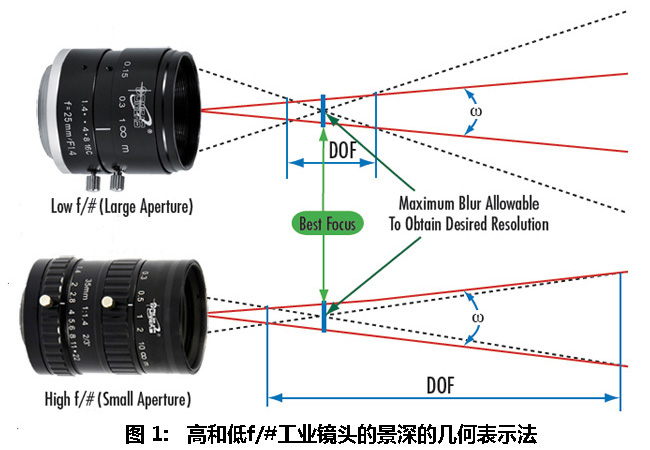

For each configuration shown in Figure 1, there are two beams of light. The black dotted line represents the distribution of information as it moves from the object to the industrial lens system. As the object moves away from the best focus position (dotted line intersection), the object details move to a wider cone area. The wider the taper is, the more blurred the boundary between the information from the industrial lens and all the other information surrounding it. The industrial lens f / # controls the speed of the tapered extension, which in turn controls how much information or detail is blurred at a given distance.

The figure also has a red cone, with the angle that the system's resolution. Where the intersection of two tapered lines can define the entire range of depth of field. Changing the f / # of an industrial lens changes the depth of field. The lower the f / #, the faster the black dotted line extends and the lower the depth of field.

As the details become smaller, the beams in Figs. Ia and Ib approach together, accelerating this effect. Finally, too much increase in f / # will cause the smaller details to become blurred due to reaching the diffraction limit of the industrial lens, since the lens's limit resolution is inversely proportional to f / #. This restriction means that although increasing f / # always increases the depth of field, the parsable (even at the best focus) feature size will increase. For more information on diffraction limits and their relationship to f / #, see Diffraction Limits. The use of short wavelengths in this region can be extrapolated and resolution losses can be recovered in a number of ways. For more information about changing wavelengths that affect system performance, see How wavelengths affect performance.

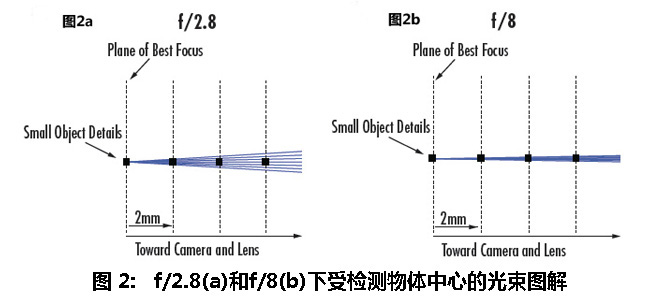

Figure 2 depicts the center of the object under f / 2.8 (a) and f / 8 (b). The vertical line indicates that the lens is moved away from the optimum focus in 2mm increments. Each vertical line has a square that represents a single pixel detail. Figure 2a shows that as the beam width exceeds the feature size, the number of required details quickly becomes a finite part of each beam. In Figure 2b, the beam spread is much slower and the details are larger than the beam diameters shown at all distances, making it a major information contributing factor and therefore easier to distinguish.

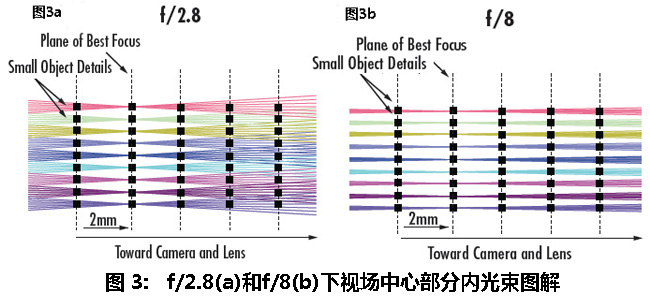

Figure 3 shows a diagram of the same type as Figure 2, but the former has a tapered representation of the multipoint in the depth of field, which in fact represents the interrupted information of the line pair. The overlapping portions of the light beams in Figure 3a show how the information converges faster than Figure 3b. This example shows how information from two different object details can be blurred by a lower f / #. In Figure 3b, this is not the case because the f / # of the industrial lens is high.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com