Influencing Factors of Imaging Quality and Aberration Classification of Optical Lens

What factors affect the image quality of optical lens?

The imaging quality of different industrial lenses varies greatly, even for the same type of industrial lenses. This is mainly due to different factors such as material, processing accuracy and lens structure. At the same time, the price of industrial lenses of different grades varies greatly from several hundred to tens of thousands of yuan.

Optical Transfer Function (OTF) is generally used to evaluate the imaging quality of lens for lens design and manufacturers. The optical system transmits the information of brightness distribution along the space. The sinusoidal wave signals of various spatial frequencies transmitted by the optical system when transmitting the information of the subject are all spatial frequencies. The modulation degree and phase change when the actual image is formed are all spatial frequencies. This function is called the optical transfer function.

OTF is generally composed of MTF (Modulation Transfer Function) and PTF (Phase Transfer Function).

Classification of aberrations

Aberration is an important factor affecting image quality. There are six common aberrations in optical systems.

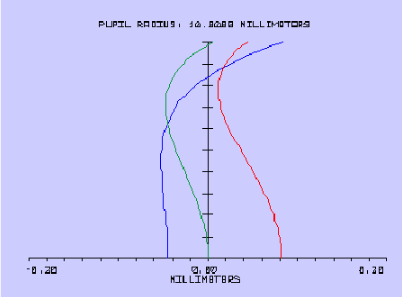

1. Spherical aberration: A monochrome conical beam emitted from an object point on the main axis to an optical system is refracted by the optical series. If the light rays of the original beam with different aperture angles cannot intersect at the same position on the main axis and form a diffuse spot (commonly known as a blur circle) on the ideal image plane on the main axis, then the imaging error of the optical system is called spherical aberration.

2. Coma aberration: A monochrome conical beam emitted to an optical system from an external object point on an axis outside the principal axis is refracted by the optical series. If it can not form a clear point at the ideal image plane, but a comet-shaped spot with a bright tail, the imaging error of the optical system is called coma aberration.

3. Astigmatism: An oblique monochrome conical beam emitted from an external object point on an axis outside the principal axis to an optical system can not form a clear image point after refraction by the optical series, but can only form a diffuse spot. The imaging error of the optical system is called astigmatism.

4. Field curvature: The imaging error of the optical system is called field curvature if the clear image of a plane object perpendicular to the principal axis is not in an image plane perpendicular to the principal axis but on a curved surface symmetrical to the principal axis, i.e. the best image plane is a surface. When the image is focused to the center of the picture, the image around the picture is blurred; when the image around the picture is clear, the image at the center of the picture begins to blur again.

5. Chromatic aberration: A white beam of light is emitted from a white object to an optical system. After refraction by the optical system, the colored light can not converge at one point and form a color image spot, which is called chromatic aberration. The reason for the color difference is that the refractive index of the same optical glass is different for different wavelengths. The refractive index of short wave light is higher than that of long wave light.

6. Distortion: The imaging error of the optical system is called distortion when the line outside the principal axis in the plane of the object is transformed into a curve after imaging by the optical system. Distortion aberration only affects the geometric shape of the image, but does not affect the clarity of the image. This is the fundamental difference between distortion and spherical aberration, coma aberration, astigmatism and field curve.

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com