Visual light source has white, blue, red, green, infrared, ultraviolet and other colors. The wavelength of each color is different, and it can also be used in different scenes.

Introduction to the applicable scenes of light sources of various colors:

White Light Source (W)

White light source is usually defined by color temperature. The color with high color temperature is blue (cold color, color temperature > 5000K), and the color with low color temperature is red (warm color, color temperature < 3300K). It is called intermediate color between 3300 and 5000K. White light source has wide applicability and high brightness, especially when taking color images.

Blue Light Source (B)

Blue light source wave and light between 430 and 480, suitable for products: silver background products (such as sheet metal, turning parts, etc.), metal printing on film.

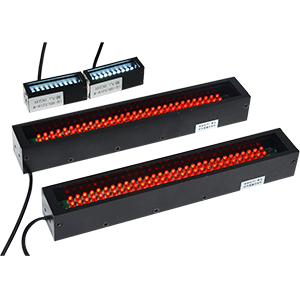

Red Light Source (R)

The wavelength of red light source is usually between 600 and 720, and its wavelength is relatively long. It can pass through some darker objects, such as black transparent soft board hole location, green circuit board circuit line detection, transparent film thickness detection, etc. The use of red light source can improve the contrast.

Green Light Source (G)

Green light source wavelength 510-530, between red and blue, mainly for products: red background products, silver background products (such as sheet metal, turning parts, etc.).

Infrared light (IR)

Infrared light usually has a wavelength of 780-1400. Our company mostly uses 940-wavelength infrared light. Infrared light is invisible, and its transmission is strong. Generally, LCD screen detection and video surveillance are widely used in the industry.

Ultraviolet (UV)

Ultraviolet wavelength is generally 190-400. Our company mainly uses 385-wavelength ultraviolet light, which has short wavelength and strong penetration. It is mainly used in certificate detection, touch screen ITO detection, fabric surface damage, dispensing glue overflow detection, scratch detection on metal surface, etc.

What are the lighting methods of the light source?

Common lighting methods are as follows: front lighting method; back lighting method; structured lighting method; mixed multi-mode lighting; special lighting method.

Vertical illumination of light source

Features: Large irradiation area, good uniformity of light, suitable for large area lighting. It can be used to locate the substrate and circuit board, inspect wafer parts, etc. (0-angle annular light source, surface light source).

Angular irradiation

Characteristic: At a certain working distance, the beam is concentrated, the brightness is high, the uniformity is good, and the irradiation area is relatively small. Usually used for LCD calibration, plastic container inspection, workpiece screw hole positioning, label inspection, pin inspection, IC printing inspection, etc. (30, 45, 60, 75, etc.). Pay attention to the angle of the light source.

Low-angle irradiation

Features: Strong expression of concave and convex surface. It is suitable for inspecting scars on wafers or glass substrates (90 degree annular light*).

Backlight irradiation

Characteristics: The luminous surface is a diffuse surface with good uniformity. It can be used for specular reflective materials, such as scratch detection on wafers or glass substrates, LCD detection, size, shape and target testing of micro electronic components. (Backlight, parallel backlight).

Multi-angle irradiation

Features: RGB three different colors and different angles of illumination, can achieve three-dimensional solder joint information extraction. It is suitable for soldering parts, spherical or semi-circular objects, other strange shape objects and connectors (AOI light source) of assembly machine boards.

Coaxial illumination

Characteristic: Similar to the application of parallel light, the light source has a diffuse reflector in front, forming a secondary light source, and the light mainly tends to be parallel. It is used for surface imaging detection of semiconductor, PCB board and metal parts, and for measuring the shape and size of micro-components. (coaxial light source, parallel coaxial light source)

How to choose the shape of the light source?

Strip light

1. The width of strip light illumination should be greater than the detection distance. Otherwise, the long illumination distance may cause the brightness difference, or the short distance and the insufficient radiation area.

2. The length of strip light can illuminate the position needed to be lighted. It does not need to be too long to cause installation inconvenience, but also increases the cost. Generally, the installation height of the light source will affect the length of the selected strip light. The higher the height is, the longer the length of the light source is required. Otherwise, the brightness on both sides of the image is darker than in the middle.

3. If the illumination target is a high reflective object, it is better to add a diffuser board. If it is a dark non-reflective product such as black, you can also remove the diffuser board to improve brightness.

Annular light

1. Understand the installation distance of light source and filter out some angle light source. For example, if the installation size of light source is high, large angle light source can be filtered out and small angle light source can be selected. Similarly, the higher the installation height, the larger the diameter of light source is required.

2. The target area is small, and the main characteristics are in the middle of the surface. Small size 0 angle or small angle light source can be selected.

3. If the target needs to display features at the edge, 90 degree angle annular light or large-scale high-angle annular light can be selected.

4. To detect scratches on the surface, 90 degree angle annular light can be selected, and the light source with short wavelength can be selected as far as possible.

Strip combined light

1. When choosing the bar combination light, it is not necessary to choose the type according to the data type. Because the shape and size of the measured object are different, different bar light sources can be selected according to the target size for combination.

2. When choosing the combination light, we must consider the installation height of the light source, and then select the corresponding strip light according to the length and width of the measured feature points on the four sides.

Backlight/Parallel Backlight

1. When choosing backlight, choose the appropriate size of backlight according to the size of the object, so as not to increase the cost and cause waste.

2. The brightness of the backlight is lower than that of the middle part because of the shelter around the backlight. Therefore, when choosing the backlight, we should try not to make the target located at the edge of the backlight.

3. Backlight sources are generally in the.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com