What is the difference between a tool microscope and a quadratic element?

Tool microscope is a mechanical optical instrument based on optical aiming and coordinate measurement, which can accurately measure the size, angle, shape and position of various workpieces, as well as parameters such as threads. It is suitable for measuring rooms and inspection stations in machinery manufacturing, precision tools, mold manufacturing, instrumentation manufacturing, electronics industry, plastics and rubber industries, etc.

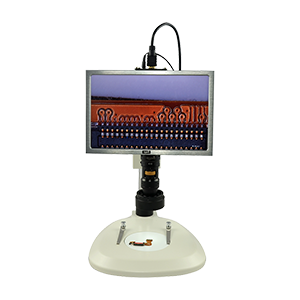

The two-dimensional measuring instrument adopts a high frame rate industrial camera, a high-definition industrial lens and a cross-hair generator as the measuring and aiming system; the digital measuring and data processing system is composed of a two-coordinate workbench, a grating ruler and an electric box; it has a variety of data processing, The display, input and output functions, especially the workpiece alignment function, are very practical; after connecting with the computer, the measurement graphics can be processed and output by using special measurement software. The two-dimensional measuring instrument is used in the application field for surface size measurement, and is widely used in machinery, electronics, instrumentation, plastics and other industries.

The difference between a two-dimensional measuring instrument and a tool microscope:

First, Differences in structural design

1. The design structure of the quadratic element measuring instrument is relatively simple, and the measurement range can be maximized according to customer requirements.

2. The design of the tool microscope is very compact and precise, and the pure optical measurement system is reserved. The eyepiece and the objective lens are used for observation and measurement. The transmission adopts the bearing guide rail, which has high measurement accuracy and can cooperate with various accessories for various measurement work.

Second, the measurement operation is different

1. The two-dimensional measuring instrument has a fast measurement speed for two-dimensional workpieces, and the software has many functions. Many measurements are completed by software.

2. The measurement range of the tool microscope is wide, and some parts measurement must be completed by accessories. The height measurement can also be performed under the high magnification objective lens, which has certain technical requirements for the operator. After the software is equipped, it has all the functions of the two-dimensional measuring instrument.

Third, the measurement range is different

1. The two-dimensional measuring instrument is more suitable for measuring flat two-dimensional workpieces.

2. The tool microscope can be equipped with various accessories such as indexing head, round table, thimble frame, etc. to increase the measurement range.

Pomeas is a professional vision system manufacturer. Its products include optical lenses, quadratic dimension measuring instruments, video microscopes and tool microscopes, etc., providing complete solutions for the diverse needs of different customers.

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com