The Importance and Solutions of Dimensional Inspection of Plastic Parts

In recent years, with the rapid development of the plastic industry and the continuous improvement of plastic performance, plastic parts have been more widely used. Plastic parts are replacing traditional metal parts in different fields. A properly designed plastic part can often replace multiple Traditional metal parts, so as to achieve the purpose of simplifying the product structure and saving manufacturing costs.

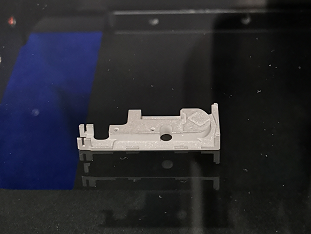

The quality of plastic parts is very important in industrial production. Quality inspection is the main means to ensure the quality of plastic parts. Quality inspection includes appearance inspection and dimensional inspection. Dimensional inspection refers to the requirements to ensure the function and interchangeability of plastic parts. In the process of processing, it must be produced in strict accordance with the requirements of the drawing tolerance. Then, according to the actual situation of the workshop, the size of the workpiece is measured with commonly used measuring equipment, and the obtained dimensional data is compared with the tolerance specified in the drawing to judge whether it is qualified or not. the process of.

There are many dimensional measurement tools in industrial production, such as digital calipers, measuring projectors, etc. Due to the different environmental conditions and the accuracy of the measurement tools, different measurement methods are required for different plane dimensions on the same workpiece. The actual size values are not the same, which brings great difficulty to the evaluation of dimensional accuracy.

solution:

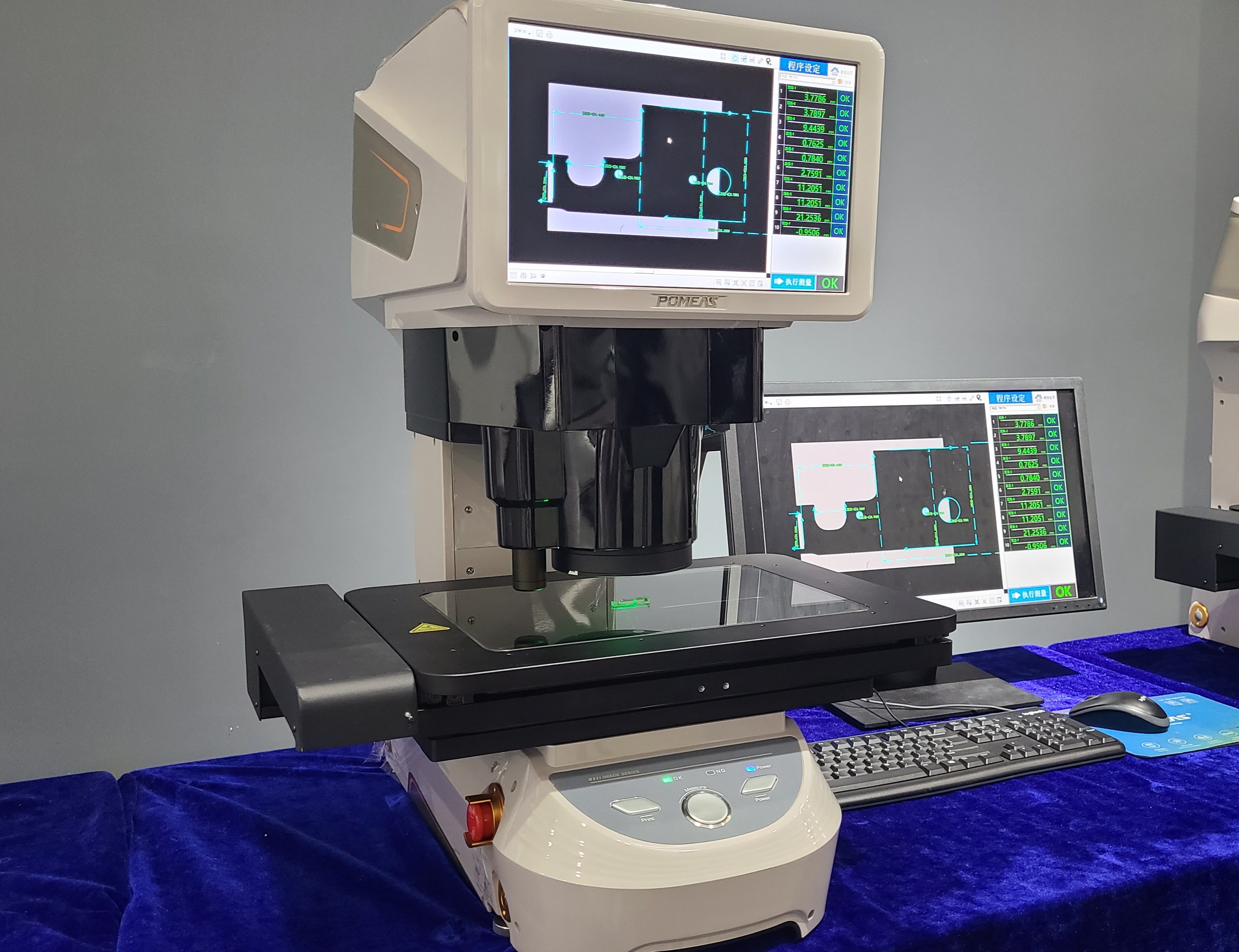

POMEAS IMAGE3 image size measuring instrument is equipped with dual industrial cameras, large depth of field and high magnification dual telecentric industrial lenses and self-developed AI image processing algorithms, which can achieve high-precision measurement of plastic parts size. Purmis's new image measuring instrument is equipped with point spectrum, which can not only measure the plane size of plastic parts, but also the height size of plastic parts.

Program advantages:

1. The system operation interface is simple and easy to understand and quick to use, which can easily write programs and set parameters;

2. With auto-focusing and auto-positioning functions, the workpiece can be automatically measured with one key after the workpiece is placed, and nearly 100 parts can be measured in 1 second, and the measurement speed is fast;

3. The measurement range is 200x300, which can measure multiple workpieces at the same time, with high measurement efficiency and saving time and cost;

4. The test report can be output with one key, and it supports a variety of formats for easy viewing.

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com