In the manufacturing industry, with the rapid development of the production industry, industrial components become smaller and smaller, and it becomes more difficult to maintain high-quality production. Ordinary amplifier materials often do not have sufficient magnification to inspect products. Video microscopy is a very flexible tool with high-contrast imaging and connectivity, providing clear and rigorous analysis and observation in numerous industrial applications. Such as the following scenarios:

1. Tool quality inspection

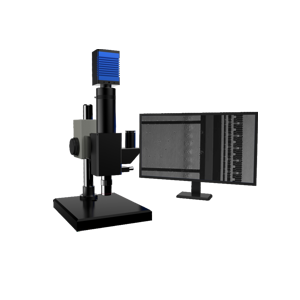

In the industrial manufacturing process, the quality of the knives directly affects the quality of the finished product, and the tiny scratches on the knives are invisible to the naked eye, and a slight error will have a serious impact on the product. The Pomeas autofocus video microscope is equipped with a zoom industrial lens and a Gigabit Ethernet industrial camera, which can clearly obtain tool images, intuitively detect defects on the tool, and improve the accuracy of tool inspection. And the product is easy to carry and can realize on-site inspection.

2. Automobile workpiece detection

The automotive industry quality control laboratory often needs to process a large number of samples of different varieties and sizes, so it is necessary to have a tool that can quickly achieve a large number of analytical results for samples of various sizes and structures in a short time. The video microscope can directly observe the sample on the display without eyepieces, and obtain inspection results more intuitively, and all inspections can obtain accurate and consistent results, and the data is more reliable. It can meet the high-precision detection requirements of automotive workpieces.

3. Circuit board quality inspection

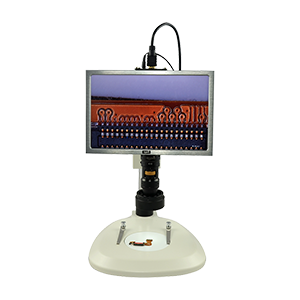

As the main board or substrate of electronic and electrical components, the quality of the printed circuit board is very important. The video microscope can convert the physical image seen under the lens through digital-to-analog conversion to make it image on the connected 4K high-definition display. Therefore, we can more intuitively use the display screen to detect whether there are defects such as false welding, incompleteness, disconnection, dislocation, etc., to eliminate defective products and avoid waste products. The operation process is fast, effectively improving the inspection efficiency and meeting the requirements of circuit board quality inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com