Advantages of Image Dimension Measuring Instrument: Splicing Measurement

The image dimension measuring instrument is a quick dimensional measurement equipment consisting of camera, light source, industrial lens, image processing system, etc. It does not require too much operator involvement and has the characteristics of non-contact, high stability, high precision, and fast measurement, which can effectively improve production efficiency and reduce labor costs.

In addition to being used for dimensional inspection of small precision parts, POMEAS image dimension measuring instrument is also widely used in splicing measurement of large-sized parts. The following are the advantages of image measuring instruments:

1. High accuracy: The image measuring instrument is equipped with a high-resolution bi-telecentric optical lens with low distortion rate and high-precision algorithm processing, with a measurement accuracy of ±2μm.

2. Fast measurement speed: Place the product arbitrarily, the instrument will automatically identify it, and measure with one botton. The entire measurement process can be automated, making it more intelligent and convenient.

3. Simple operation and easy to use: POMEAS image measuring instrument does not require complicated training, and anyone can easily get started. Measurement data are generated on-site, evaluation results are automatically generated, and statistical reports are generated with one botton. The saving format can be exported as needed, which is of great help in later data statistics and analysis.

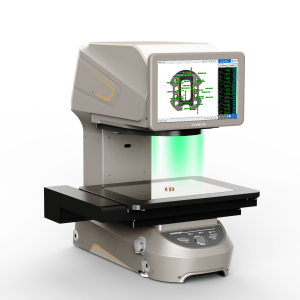

POMEAS image dimension measuring instrument splicing application cases:

1. PCB board dimension measurement: Measure uncut PCB boards, measure multiple products at the same time, and use splicing mode to obtain all images at one time and quickly complete surface dimension inspection.

2. Auto parts inspection: In automobile manufacturing, dimensional inspection of parts such as body parts is required. For some larger workpieces, the use of POMEAS image measuring instrument can greatly improve measurement efficiency and measurement accuracy.

3. PAD glass size inspection: In the manufacturing of PAD glass, its dimension requirements are very strict, and quality inspection needs to be done. The POMEAS image measuring instrument can achieve high-precision, high-speed and stable measurement.

POMEAS image measuring instrument is widely used in splicing measurement of large-size parts, and has strong adaptability and feasibility.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com