How to Choose the Right Dimensional Inspection Method

The best way to choose the right dimensional inspection method is to consider the following factors:

The part geometry: The part geometry will determine the type of measuring tool that can be used. For example, a part with a complex geometry may require a CMM, while a part with a simple geometry may be able to be measured with a micrometer.

The tolerances: The tolerances that need to be met will determine the accuracy of the inspection method that is required. For example, a part with tight tolerances will require a more accurate inspection method than a part with loose tolerances.

The production volume: The production volume will determine the cost of the inspection method that can be used. For example, a high-volume production run will require an inspection method that is cost-effective.

The budget: The budget will determine the type of inspection method that can be used. For example, a low-budget project will require an inspection method that is inexpensive.

The expertise of the inspection team: The expertise of the inspection team will determine the complexity of the inspection method that can be used. For example, a team of experienced inspectors may be able to use a more complex inspection method than a team of inexperienced inspectors.

Dimensional inspection is essential for ensuring the quality of manufactured parts. By choosing the right inspection method, you can improve productivity, quality, and cost-effectiveness.

Here are some tips for conducting accurate dimensional inspections:

Use the right measuring tools for the job.

Follow the manufacturer's instructions for using the measuring tools.

Take multiple measurements and average them to get a more accurate reading.

Make sure the part is clean and free of debris before taking measurements.

If you are not sure how to perform an inspection, ask for help from a qualified professional.

By following these tips, you can help to ensure that your manufactured parts meet the required specifications and are safe to use.

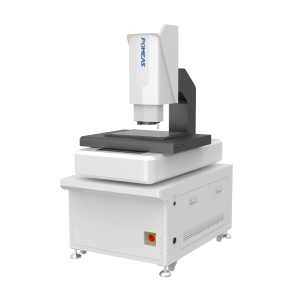

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com